Chemical

We offer a number of materials that can withstand the chemical resistance, high purity, and high operating temperature.

Dechengwang manufacture PTFE Seals for Aerospace, Automotive, Semiconductors, Oil and Gas sectors. Materials include PTFE, Filled PTFE, PEEK, PFA, PVDF and PCTFE.

PTFE cup seals

PTFE Seal 1

PTFE Seal 2

PTFE Seal 3

PTFE Seal 4

PTFE Seal

PTFE components are necessary in some critical industries. We understand your challenges, and you will have our words on your PTFE component requirements.

Components in small or large volume order maintain tight tolerance of 0.01mm, offering tight precision consistency.

Each and every component we produce are recorded and traceable under ISO quality management system.

We are capable of providing cost-effective planning of compatible machining techniques, in quick lead time.

Dechengwang is a certified manufacturer, confirmed by audits, to many major OEM companies. We specialize in the manufacture of high performance polymer components for industrial applications.

In spite of natural color of polymer, customized color is available: white, blue, transparent and more.

All size and shape are available. Just specify your machined part size and dimensions (diameter, section and length)

Virgin PTFE, filled PTFE or other plastic materials are available for reinforced components.

All of our products are available with no minimum order quantity, no hidden setup charges and fast lead times.

With compression presses, our engineers are consistently producing a wide range of Fluoropolymer plastic rods and tubes that are quality enough to be used in the petrochemical industry, economically and efficiently.

Our compression molding is ideal solution for contract manufacturing, with custom shapes and colors.

PTFE, filled PTFE or any fluoropolymers can achieve best molding effects in our cleanroom compression.

Tightest tolerance of ±0.01mm, based upon part geometry, material selection and process.

From prototype to bulk production, our compression molding features no MOQ.

Compression Molding Plant

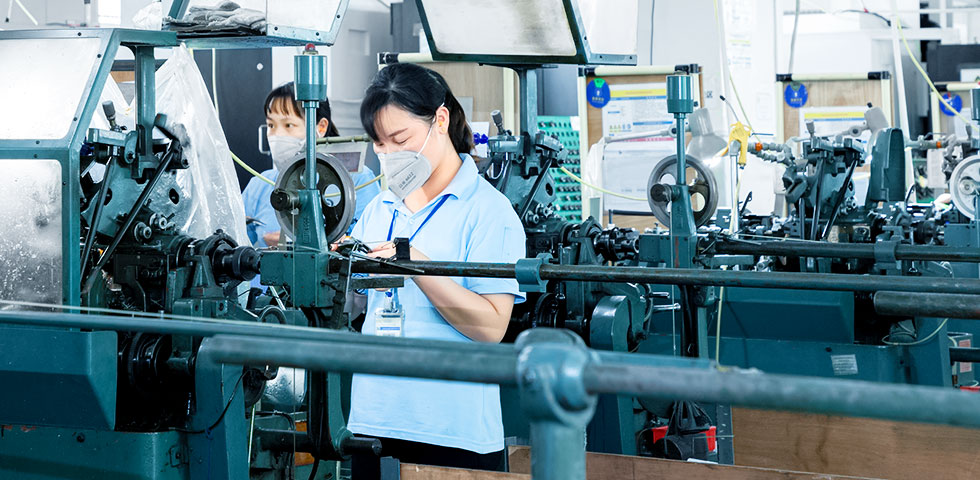

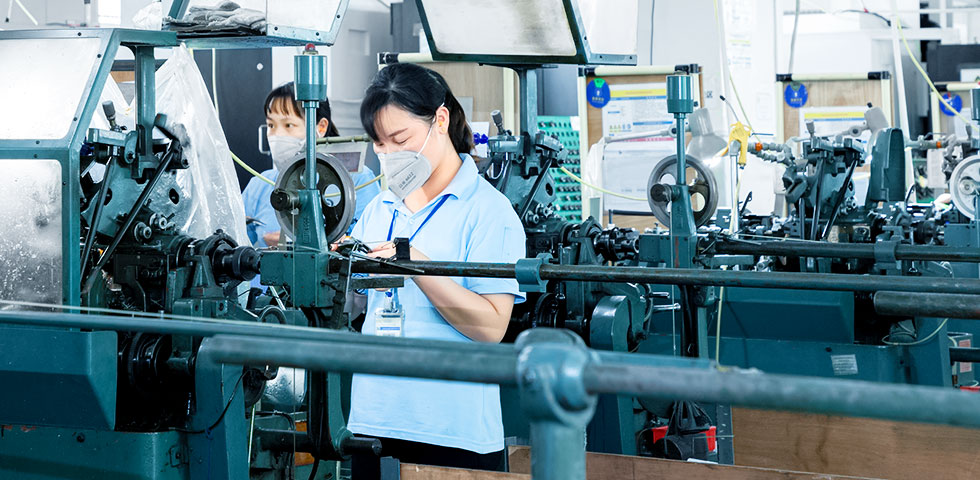

Automatic Machining Plant

Screw Machining Plant

CNC

Machining Plant

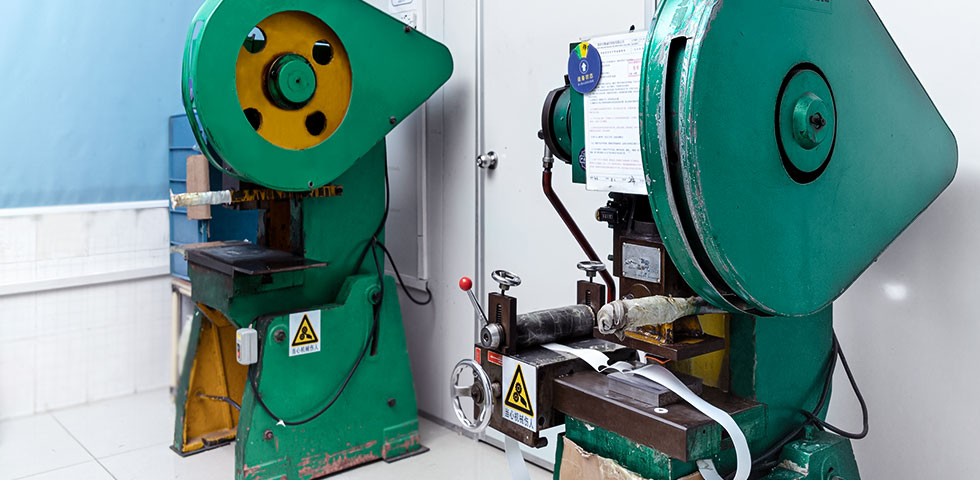

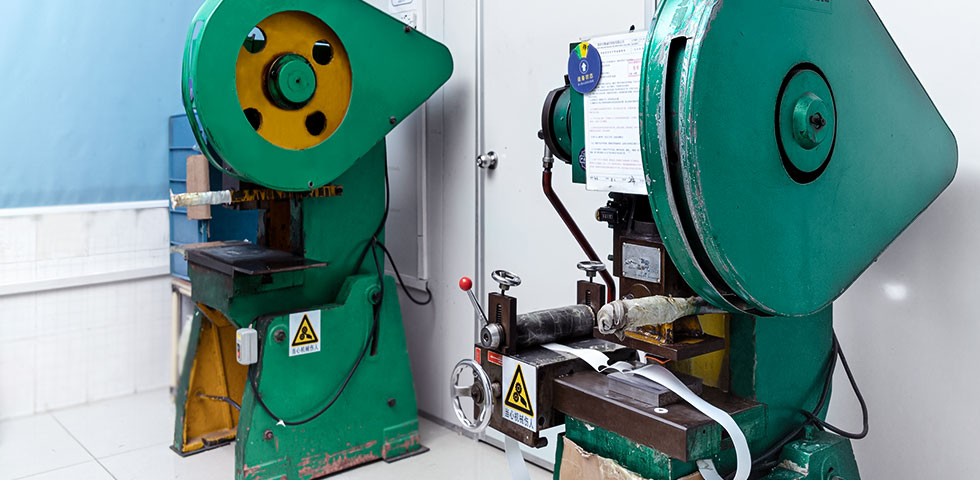

Stamping Plant

Our factory is a hub of a number of state-of-the-art machines, which means that we can manufacture your PTFE and compounding project on time and at all times. To find out more about our machinery and process, explore our factory images below.

We offer a number of materials that can withstand the chemical resistance, high purity, and high operating temperature.

Engineering thermoplastics to support the food industry’s need for reliable, traceable, and cost-effective machine parts.

Impress with low weight characteristics, excellent chemical resistance, and fire behavior.

Increase performance and safety, and reduce fuel consumption and environmental impact.

A combination of highest quality, tightest tolerances, excellent dielectric properties at high temperature makes our parts your best choice.

Combining tightest tolerances, slipping characteristics and small friction coefficient makes PTFE the correct option.

Our virgin and compounding materials can withstand the extreme temperatures and harsh chemicals.

Need custom solutions for you industry? Contact us for FREE consultation.

ISO 9001 2015 Quality Management System Certification 2018

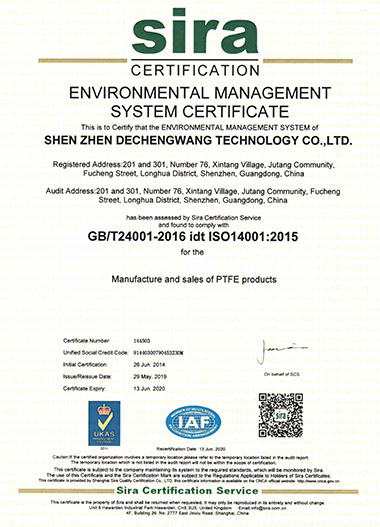

ISO 14001 2015 Environment Management System Certificate 2018

Intellectual Property Managements Certificate 2019