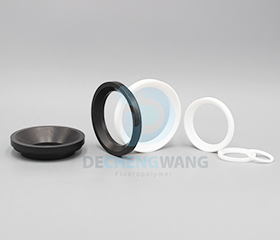

Machined Fluoropolymer Components

A wide range of machined applications in PTFE, PTFE compounds, PEEK, PFA, PVDF and PCTFE materials.

More than PTFE

The knowledge and experience is a needed for processing Fluoropolymer material. Having over 10 years experience and in-house compounding capabilities helps Dechengwang to reduce throughput time and costs.

Various Processing Techniques Ready

In-house PTFE compression molding, CNC turning, CNC turn-mill, Multi axis, grinding, tapping, etching, annealing, stamping, and other processing centers are ready 24/7 to achieve your desired part shape. Take advantage of our fluoropolymer parts machining capabilities.

Cleanroom Manufacturing

Dechengwang operates cleanrooms dedicated to manufacturing PTFE components the semiconductor, food/dairy and pharmaceutical/medical industries. Environmental parameters such as temperature, humidity and pressure are carefully controlled.

Raw Material Assured by FDA & RoHS

It is our intention to assist our customers in full compliance with the legal requirements of FDA and RoHS. Also you can benefit from our ISO certified in-house quality inspection, which provides traceability of each batch.