PTFE Bushings

PTFE bushings are the maintenance-free solution for heavy load/medium speed applications. Dechengwang offers a wide range of both straight and flanged PTFE bushings. Advantages of these bushings include: maintenance-free operation, very good frictional properties, high load carrying capacity, high operating temperature, high sliding velocity, small operating clearance.

Finished Products

Semi-Finished Products

Why Order from Us?

PTFE bushings are suitable for applications where a sliding material with self lubricating properties is a prerequisite. Application area examples for these bushings are:

- Automotive

- Material handling equipment

- Home appliances and consumer goods

- Textile machinery

Designed for Your Application

- Full self-lubricating capabilities

- No stick-slip

- Excellent cold flow resistance

- Good contamination resistance

Samples of Our Work, RoHS & FDA Compliant

Glass Filled PTFE Bushing

PEEK Bushing for 3D printer

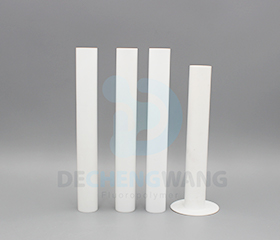

PTFE Bushing 1

PTFE Bushing 2

PTFE Bushing

ptfe bushings

PTFE Flanged Bushing

PTFE Bushings Materials Selections

| Material Name | Compound % | Main Properties | Color |

| PTFE | / | Very low coefficient of friction and excellent chemical resistance.

FDA approved. |

White |

| Glass Filled PTFE | Up to 40% | Improved ware resistance, compression strength, creep resistance, chemical resistance. Good performance in oxidising environment, good creep resistance. | White cream |

| Carbon Filled PTFE | Up to 35% | Improved electrical and termal conductivity, resistance to load, low coefficient of friction in dry, water, steam applications, chemical resistance. Superior ware resistance increase and low friction properties. | Black |

| Graphite Filled PTFE | Up to 25% | Improve wear resistance, decrease friction and increase sliding properties against soft metals- chemical inertness. Improve the temperature resistance in some way. | Black |

| Bronze Filled PTFE | Up to 60% | Improved compression strength, wear resistant, high thermal conductivity, resistance to abrasion. Reduced chemical resistance. | Dark Brown |

| Molybdenum disulphide(MoS2) Filled PTFE | up to 5% | Increased PTFE properties of hardness and wear resistance. Increased sliding properties and decrease friction. | Blue azure |

| PEEK Filled PTFE | Up to 20% | Increased thermal resistance, sliding properties, surface hardness. Superior properties on dynamic applications. | Light Brown |

| PEEK | / | Excellent mechanical properties including strength, rigidity, impact resistance, low wear rate and low coefficient of friction, retained over a wide range of service temperatures. | Light Brown |

| PEEK compound | / | Improves technical and chemical properties like deformation under load, wear resistance, thermal expansion and electrical conductivity. | / |

| PVDF | / | Resistant to UV radiation and offers high mechanical strength and abrasion resistance. | Beige |

| PCTFE | / | Better mechanical properties than other fluoropolymers, low permeability. | Translucent |

| PFA | / | Excellent chemical and temperature resistance, electrical insulation and excellent processability | Natural |