In the world of engineering and manufacturing, where precision and efficiency are paramount, the role of wear resistance plastic has evolved far beyond their conventional image. With the advent of advanced materials and innovative techniques, plastics have emerged as versatile champions in combating mechanical wear, enhancing durability, and optimizing performance. At the heart of this transformation lies a remarkable property – the low coefficient of friction and wear resistance – a characteristic that not only inhibits mechanical wear and damage but also serves as a catalyst for a multitude of benefits.

Industries spanning from automotive to aerospace, from machinery to medical devices, are embracing the transformative potential of low friction plastics. By mitigating wear and tear, these materials play a pivotal role in inhibit mechanical wear and damage, prevent contamination, reduce noise, and minimize maintenance needs.

Industrial processes and production greatly rely on the importance of low-friction plastics, primarily due to their exceptional ability to withstand wear and abrasion. To enhance these qualities even further, the inclusion of high-performance plastic introduces an extra layer of functionality. Let’s explore several noteworthy high-performance plastics ideally suited for industrial applications, PEEK, PPS, PI, and PTFE.

What is wear resistance?

Wear resistance pertains to a material’s capacity to withstand gradual surface volume loss caused by mechanical actions like repetitive rubbing, sliding, or scraping.

Materials with wear-resistant qualities diminish friction between interacting surfaces, enabling components to preserve their shape and integrity over extended periods, especially in scenarios involving contact between load-bearing interfaces.

Wear is the direct result of the same processes that causes friction – the movement of the asperities on the surfaces over one another.

The principles underpinning wear, friction, and lubrication fall within the domain of tribology – the scientific and engineering discipline concerned with studying interactions between surfaces in relative motion.

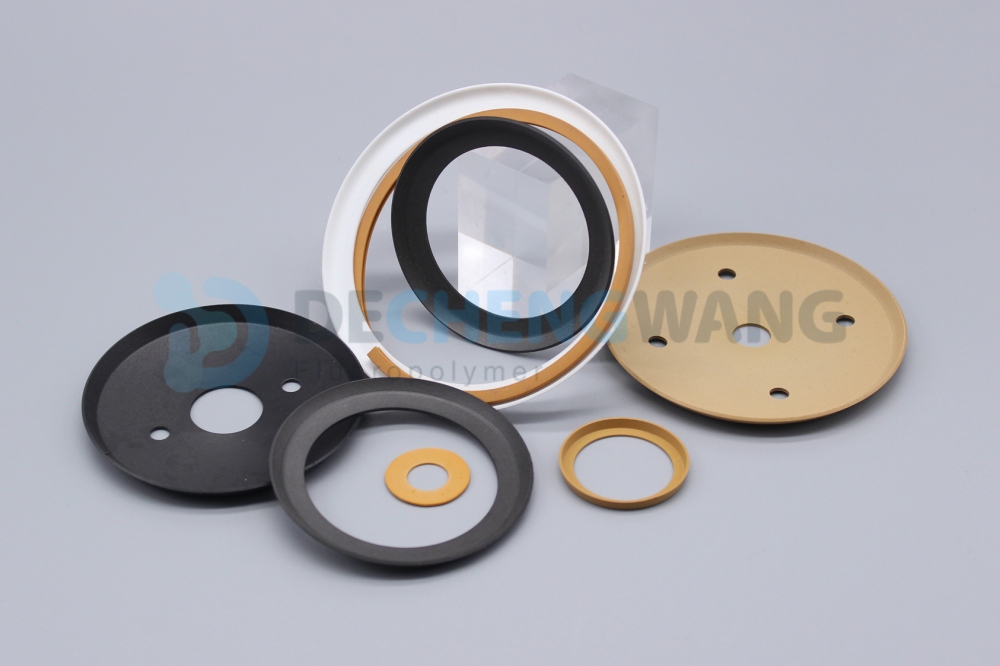

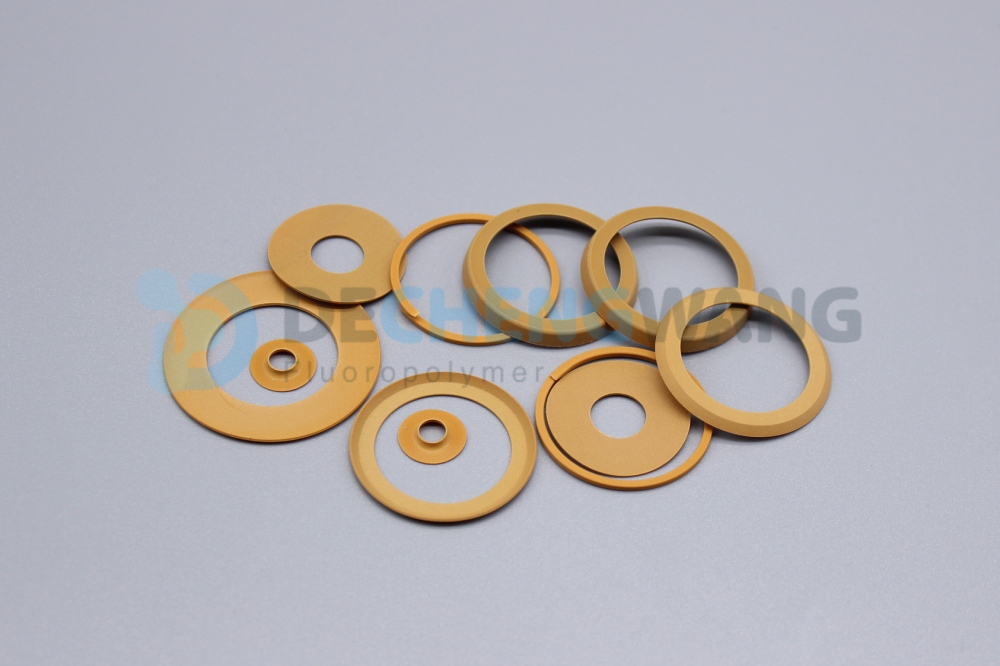

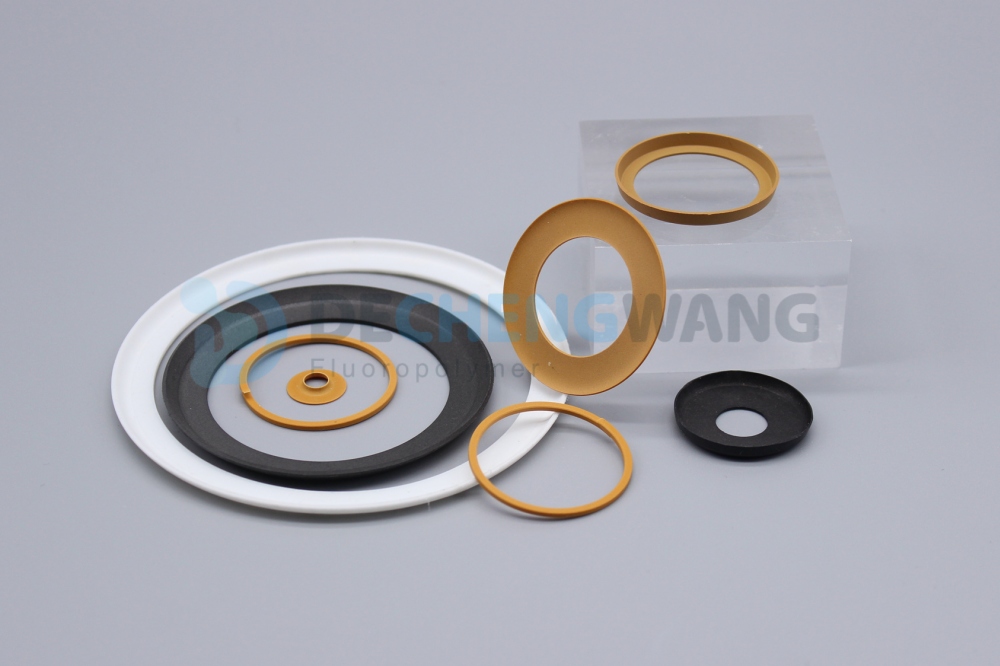

Within our products, an extensive range of high performance plastic is available, designed to curtail wear either through their inherent low-friction attributes or self-lubricating properties. These materials mitigate mechanical wear while consistently upholding performance benchmarks within applications.

A CONSIDERATIONS-Which factors influence wear resistance and wear rate?

While wear may appear to be simple there are a number of different mechanisms that can cause wear, like adhesion, abrasion, fatigue, erosion, corrosion, which Briefly summarized in the following three aspects:

Contact Method

- Dynamic contact, for example, sliding vs. rolling

- Mating surfaces, e.g. metal-on-metal vs. plastic-on-plastic vs. metal-on-plastic

- Texture or roughness of the mating surfaces, Clearance between mating surfaces

Working Environmental conditions

- Temperature, including heat generated by friction

- Exposure to sunlight

- Presence of moisture or chemicals

- Presence and type of lubrication

Load

- Pressure of the applied load

- Velocity of the dynamic movement

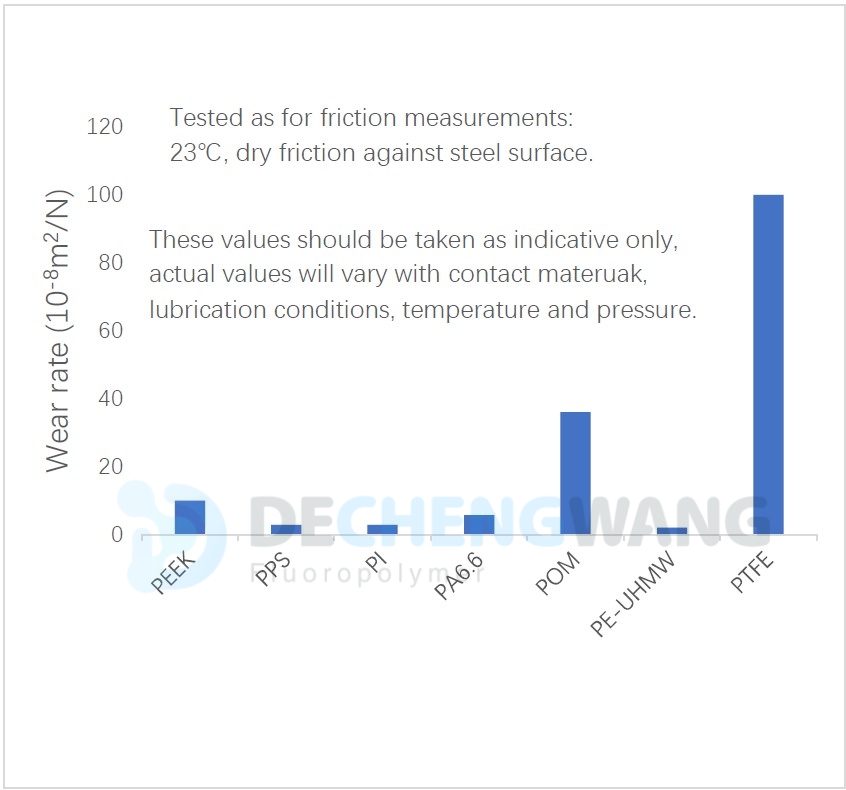

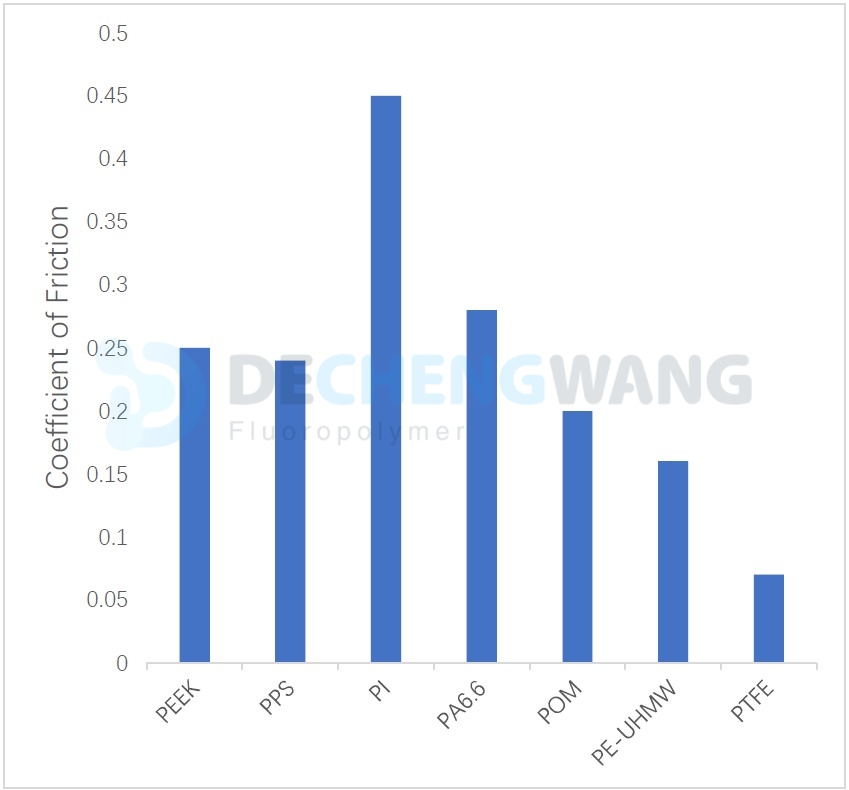

Predicting wear in actual materials is a challenging task due to the multitude of variables involved. Consequently, providing precise estimates for the wear of a particular plastic is often only feasible through indicative values, unless the plastic’s performance under specific application conditions has been empirically evaluated. The following diagram presents approximate wear values for various plastics when in contact with dry steel.

What is Friction?

Friction arises when there is resistance to the movement between two surfaces. The coefficient of sliding friction is a key factor in describing friction. It measures the strength of the frictional force compared to the normal force. A greater coefficient of sliding friction indicates a stronger frictional force. Therefore, the lower the coefficient of friction, the more smoothly two surfaces can slide against each other.

What is Abrasion and adhesion?

Various sliding and wear mechanisms come into play based on the specific sliding conditions. In the context of plastics, abrasion and adhesion take on significant roles. Abrasion involves the wear and removal of material from softer sliding partners due to the rough surfaces of harder sliding components. On the contrary, adhesion relies on surface bonds, where surface roughness and polarity are key factors determining whether adhesive wear takes place.

What is the Coefficient of Friction?

Coefficients of friction are commonly presented as values in tables; however, these values are always approximations due to the diverse array of factors influencing the coefficient of friction (material pairing, surface conditions, lubrication, temperature, humidity, wear, normal force, etc.). Thus, the practical coefficient may deviate from model test results. It’s essential to always incorporate the system parameters from model tests at the very least.

The most accurate outcomes arise from tests conducted under real-world conditions. Yet, it’s important to acknowledge that the ratios between the test results and actual applications can vary.

In numerous engineering scenarios, materials with low friction and high wear resistance are sought, such as thermoplastics. In comparative applications, high performance plastics generally exhibit a lower coefficient of friction than metals. Furthermore, advanced plastic materials frequently possess self-lubricating attributes, rendering them well-suited for prolonged usage and load-bearing situations.

When contrasted with metals or other interacting surfaces, wear-resistant high performance plastics deliver numerous advantages in high-friction scenarios:

- Reduced friction and inherent self-lubrication diminish the need for external lubrication.

- Predictable wear rates curtail unscheduled maintenance and downtime.

- Enhanced operational dependability and extended mean time between repairs (MTBR).

- Diminished noise generation between engaged components.

- Within food contact applications, there’s a lowered risk of contamination from material particles and lubricants.

Top-Performing Low-Friction High-Performance plastic

As previously mentioned, industries demand low-friction plastics to enhance operational efficiency. These specialized materials offer impressive wear resistance. Furthermore, high-performance plastic not only provide corrosion resistance but also contribute to weight reduction and decreased heat and friction. These attributes translate into extended part lifespan and reduced maintenance expenses.

- PTFE (Polytetrafluoroethylene)

PTFE, also recognized as polytetrafluoroethylene or Teflon®, stands as a semi-crystalline fluoropolymer known for its exceptional thermal stability, chemical resistance, and high melting point. Often utilized as an additive to polymers like polyamide, polyacetal, polyester, polycarbonate, and TPE, PTFE imparts remarkable sliding capabilities, electrical resistance, and a non-stick surface.

Nonetheless, PTFE exhibits relatively low mechanical strength and a higher specific gravity in comparison to other plastics. The incorporation of additives such as glass fiber, carbon, or bronze can enhance its mechanical properties. PTFE is prominently employed in chemical plant engineering and applications requiring high chemical stress with sliding components.

- PEEK (Polyetheretherketone)

PEEK, also referred to as polyetheretherketone, stands as a distinctive semi-crystalline engineering thermoplastic renowned for its excellent chemical compatibility. Capable of functioning at temperatures up to 480°F with a melting point around 646°F, PEEK materials excel in hot water or steam environments, maintaining impressive flexural and tensile strength even in challenging conditions. Components manufactured from PEEK material exhibit reduced weight, enhanced strength, and prolonged durability under harsh circumstances.

- PI (Polyimide)

PI, or polyimide, emerges as a non-melting high-temperature polymer renowned for its robustness, dimensional stability, and resistance to creep even at temperatures exceeding 500°F. Its suitability for demanding friction and wear scenarios stems from its low wear rates, ability to function in unlubricated conditions, and high pV-rates. PI finds application in industries such as vacuum, space, and semiconductor due to its high purity and minimal outgassing.

- PPS (Polyphenylene Sulfide)

PPS, or polyphenylene sulfide, constitutes a semi-crystalline high-temperature thermoplastic with exceptional chemical resistance. Exhibiting robust mechanical strength, even at temperatures surpassing 392°F, PPS boasts commendable dimensional stability and impressive electrical properties. This material sees use in diverse sectors including electronics, automotive, medical, mechanical engineering, and the chemical industry.

Effortlessly Elevate Your Plastic Manufacturing with DCW professional Team, contact us for more questions of high performance plastic.