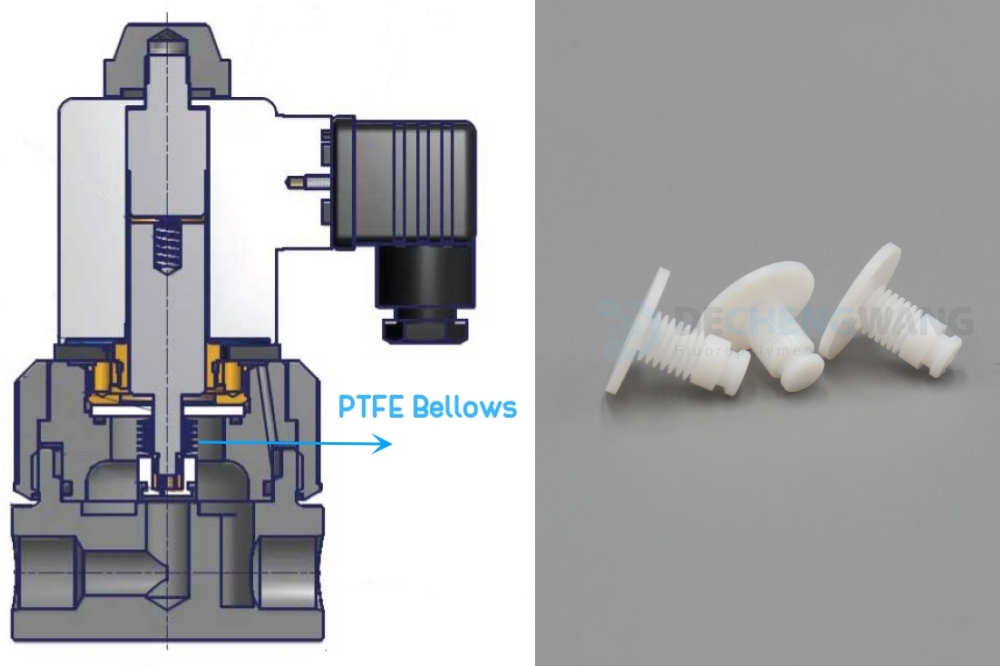

Bellows Mechanical Seal are a type of mechanical seal where the spring element is a bellows. They are a critical component in preventing fluid or gas leakage from rotating equipment such as pumps, mixers, and valves. The bellows, usually made of PTFE, rubber and metal. In today’s topic, we will focus our attention to PTFE Bellows.

What is PTFE Bellows?

PTFE Mechanical bellows seals are a specialized category within the realm of Bellows Mechanical Seals, constructed primarily from Polytetrafluoroethylene (PTFE) or modified PTFE materials. These meticulously engineered components play multifaceted roles, serving as pulse dampeners, compensatory elements, and protective barriers in a wide array of applications across the chemical, food, and medical industries.

At their core, PTFE bellows function as indispensable barriers within machinery, meticulously safeguarding the integrity of operations by preventing the escape of hazardous substances. These bellows are aptly categorized as Bellows Mechanical Seals, and they distinguish themselves by their distinctive design. Unlike their counterparts, known as pusher seals, PTFE bellows feature a static secondary seal that remains securely in place, whether it’s nestled against the rotating shaft, sleeve, or within the pump’s gland.

In essence, PTFE bellows represent an ingenious fusion of advanced materials and precision engineering, seamlessly contributing to the efficient and reliable functioning of machinery in industries where safety, hygiene, and precision are non-negotiable.

The Benefit.

PTFE bellows play a pivotal role in a myriad of applications by serving as essential balancing elements between various engineering components. This versatile material finds extensive utilization in industries spanning from chemical processing to food production and even within the realm of medical appliances, owing to its exceptional properties and durability.

- Universal Chemical Resistance

In the realm of chemical processing, PTFE bellows are instrumental in maintaining the integrity of intricate systems. Their resistance to aggressive chemicals and extreme temperatures makes them indispensable for ensuring the seamless operation of pumps, valves, and other crucial equipment in the chemical industry. The ability of PTFE bellows to withstand the corrosive effects of acids, bases, and solvents enhances the safety and reliability of these processes.

- FDA compliant Materials

In the food industry, where hygiene and purity are of paramount importance, PTFE bellows find a prominent role. These bellows are commonly used to isolate sensitive equipment from the surrounding environment, preventing contamination and ensuring product quality. Their non-toxic and non-reactive nature, coupled with their ability to resist high temperatures, make them ideal for applications involving food and pharmaceutical products.

- Suitability for Sterilization

Furthermore, the medical sector benefits immensely from PTFE bellows due to their biocompatibility and inertness. These bellows are employed in various medical appliances, including ventilators and anesthesia machines, where their non-reactive nature ensures patient safety. It help maintain the sterility of critical components, contributing to the overall effectiveness and reliability of medical devices.

- Non-Adhesive Properties

PTFE is inherently anti-adhesive, which means it resists sticking to other materials. This makes PTFE bellows easy to clean.

- Cost-Effective Production

DCW is one of the few PTFE manufactures to be fully integrated, having the capabilities to produce a part from base resin to finished part. PTFE bellow made by DCW can be competitive on pricing.

Type of PTFE Bellows.

- PTFE Bellows for solenoid valve: High flexibility and frequency, Biocompatible, resistant to aggressive cleaning agents.

- Bellow for filling valve: The tip is the sealing cone of the valve. Hermetical separation of the medium from the actuation mechanism.

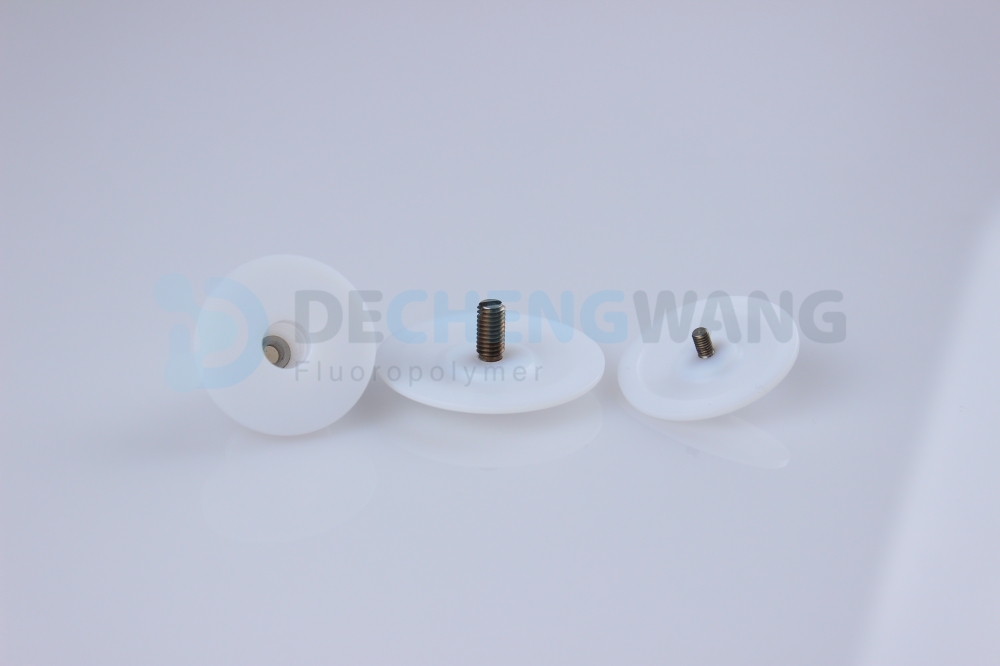

- Bellows with metal inserts: In order to introduce higher forces into PTFE bellows, a metal part is often insert.

- Bellows made of PTFE compound: PTFE Bellows are previously possible to reinforce stressed areas with PEEK.

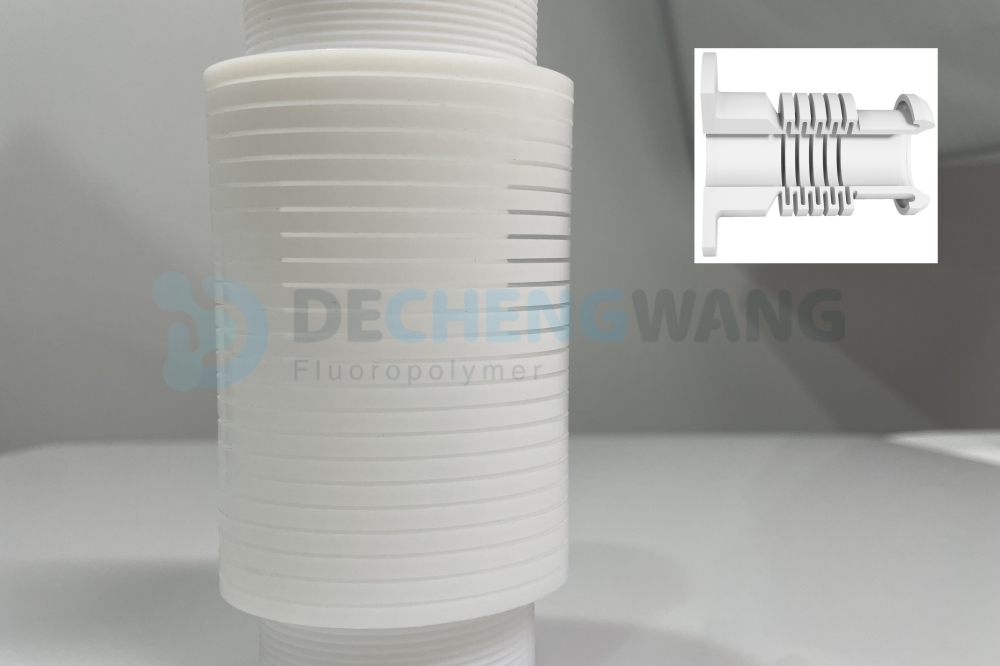

- Round folds bellows: Medium pressure stresses, Easy to clean.

- Angular folds bellows: High rigidity and allows only short stroke. Easy to clean, Stable walls and both vertically and horizontally mounted.

- Sharp folds bellows: Low-pressure stresses and high stroke frequencies. Good installation length to elasticity ratio. Well suited for use in dynamic applications.

Applications of PTFE Bellows

- In solenoid valves

- For filling systems

- In aseptic valves

- In metering deveices

- In pumps and valves

- As compensation for expansion in pipe systems

- For shielding sterile areas

- Coating technology

Material and compliant

• PTFE

• Modified PTFE

All of the material which we used for teflon bellows are compliant with

- FDA: US FDA 21 CFR 177.1550

- USP

- RoHS

- REACH

In conclusion

PTFE bellows applications range from chemical, food to medical appliances. The manifold benefits of bellows, including their universal chemical resistance, FDA compliance, suitability for sterilization, non-adhesive properties, and cost-effective production, make them indispensable components in modern engineering.

DCW is a professional manufacture of PTFE products since 2006. We are Middle size factory that are being able to react quickly but also have the capability necessary to satisfy any large project for our customers. For more information contact us info@ptfedf.com or call on 0086 13823687546.