If a PCTFE vs PTFE survey were to be conducted, arguably everyone would vote for PTFE because it’s widely used across many industries. However, there are some applications where PTFE fails to meet the requirements. This brought about the discovery of a similar but different plastic material (PCTFE) which is capable of performing highly in cases where PTFE is unable.

As a PTFE and PCTFE manufacturer with expertise in dealing with both polymers, we’ll be sharing with you everything you need to know about them. This includes what they are, their similarities and differences, as well as the best polymer to opt for.

What is PCTFE

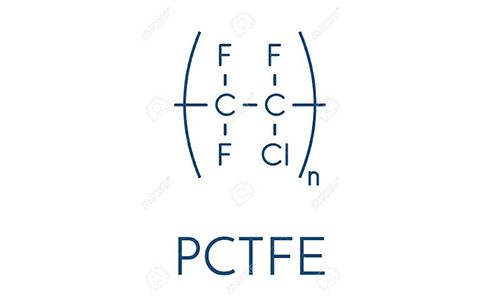

PCTFE, which stands for Polychlorotrifluoroethylene, is a strong plastic with great thermal properties. It is non-flammable and has a working temperature range of -240⁰C (-400⁰F) to 150⁰C (302⁰F) with a crystallinity of 85-90%. This polymer contains a high amount of chlorine, making it resistant to most chemicals and oxidizing agents. But it has minimal swells when it comes in contact with halogenated compounds, esters, aromatic solvents, and ethers.

Amongst all fluoropolymers, PCTFE possesses one of the highest Limiting Oxygen Index (LOI) and doesn’t absorb moisture or get wet. It possesses good light transmission, infrared, ultraviolet, and gas barrier properties. Also, it has a low thermal coefficient expansion and its dimensional stability makes it suitable as a component of a structural part that requires high temperature and resistance to chemicals.

The manufacturing process of PCTFE material is simple as it can be melted through conventional techniques like injection molding, extrusion molding, and compression molding. PCTFE can be used to make engineering plates, pipes, valve parts, suspension, corrosion-resistant pumps, electrical coating, etc.

What is PTFE

PTFE is an acronym for Polytetrafluoroethylene, which is commonly called the “King of Plastics.” It’s a multipurpose and cost-effective plastic material with an average tensile strength that’s formed by the polymerization of tetrafluoroethylene. It possesses outstanding properties, such as high resistance to heat and corrosion, as well as great chemical inertness, especially in strong acids. Aside from fluorine and molten metal sodium, it is resistant to all other chemicals.

PTFE has a broad working temperature range of -180⁰C (-292⁰F) to 260⁰C (500⁰F), making it suitable for applications that require high temperature and frequency. A very good example is an electrical insulator. Its coefficient of friction is very low and is in fact, believed to be lower than other solids.

At the molecular stage, it’s a linear plastic with a high molecular weight that has a crystallinity level of 50%-70% depending on the processing conditions. Fillers such as fiberglass, graphite, carbon, and bronze can be added to PTFE, hence boosting its basic properties.

The manufacturing technique of PTFE is quite difficult as it cannot be processed using conventional methods because of its high viscosity. Rather, it is processed by cold forming operation after which sintering is performed. During this process, the plastic will fuse to form a solid mold. It can be made into PTFE seals, gaskets, sheets, pump parts, manifolds, scientific equipment, insulation tapes, etc.

Similarities between PCTFE and PTFE

The battle of PCTFE vs PTFE exists because of the likeliness they share as the two fluoropolymers are composed of the same chemical formulas. The only difference is that PCTFE has an additional chlorine atom, hence altering its properties and functions.

Both polymers have a broad temperature range with great thermal characteristics. Also, they are resistant to chemicals and corrosion, making them the most suitable plastic materials for all applications.

Differences between PCTFE and PTFE

PCTFE is a homopolymer of chlorotrifluoroethylene (CTFE), while PTFE is a homopolymer of tetrafluoroethylene. Due to the addition of chlorine in PCTFE, it has less flexibility and cannot be elongated as much as PTFE. But PTFE is better in terms of heat resistance, dielectric strength, and friction coefficient.

In terms of hardness, strength, and other mechanical properties, PCTFE is superior. Also, it has a lower viscosity and creep resistance than PTFE. However, PCTFE chemical compatibility is lesser than PTFE.

Below is a table that further shows the PCTFE vs PTFE difference.

| PROPERTIES | PCTFE | PTFE |

| Tensile Strength | 30-35 MPa | 20-30 MPa |

| Elongation | 100-250% | 200-350% |

| Melting Point | 200-220⁰C | 350-380⁰C |

| Dielectric Breakdown Voltage | 20-40 kV/mm | 50-100 kV/mm |

| Friction Coefficient | 0.25-0.35 | 0.03-0.05 |

| Injection Molding | Yes | No |

| Chemical Resistance | Good | Very good |

| Thermal Stability | Very good | Good |

| Cost | Expensive | Less costly |

Best Option to Choose

There is no argument to the fact that PTFE is a niche material among more generic polymers, like Polyethylenes (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), and nylons. Most applications that require high temperature, resistance to chemicals, and high friction are often executed with PTFE. Manufacturers often use it for the production of items that are both insensitive to UV rays and non-toxic.

However, there are certain applications where PTFE doesn’t fit and a compromise must be made. For instance, in applications where extreme hardness, strength, and dimensional stability are required across a broad temperature range, PCTFE material is the best option.

So, the decision of which is best between the two polymers is dependent on the application it’s to be used for.

Conclusion

PCTFE and PTFE are no doubt part of the most versatile and industrious plastic materials. They are very much alike as they have similar properties, however, some differences exist mainly in the chemical structure.

In this post, we’ve done good justice to the PCTFE vs PTFE debate. For further professional guidance and order of these polymers, you can reach out to Dechengwang, the most reliable manufacturer of PCTFE, PTFE, and other polymers.