Seals are essential parts that are needed in all mechanical applications because they stop leaks and guarantee the integrity of the systems. There are various forms of sealing, and each one is designed to act as a partition between moving elements so that liquids and gases stay in their assigned spaces.

This post discusses the different types of seals, which are categorized into two – static seals and dynamic seals.

A Brief Introduction to Mechanical Seals

Mechanical seals are tools used to tighten equipment joints and apertures by preventing fluid and gas leaks, containing pressure, and acting as a shield against outside contamination. As a result, maintenance costs are reduced, efficiency is increased, and safety is improved. Mechanical seals are applicable in numerous sectors, including those in automotive, chemical, aerospace, mechanical engineering, oil and gas, electronics, food and beverage, etc.

From pumps, motors, and compressors to mixers and turbines, mechanical seals are popularly used in both rotary and reciprocating applications. Having a perfect understanding of the types, features, and applications of the different kinds of seals is essential in getting reliable sealing solutions for mechanical systems.

Different Types of Static Seals

Static seals are usually used when there is no motion between the mating surfaces. Discussed below are the three basic types of static seals, their features, and their applications.

Gaskets

Made of flat, elastomeric, or compressible materials like rubber or cork, gaskets are static seals used to fill in the space between the surfaces of stationary components. Top gasket manufacturers in the world ensure that the gaskets are built to fill irregularities and create a tight seal between flat surfaces. These kinds of seals can be made in various materials and sizes as long as it meets the desired application.

Gaskets offer excellent fluid compatibility, as well as resistance to pressure and temperature. This makes them adaptable for a variety of uses, including machinery, flanges, motors, and pipelines.

O-Rings

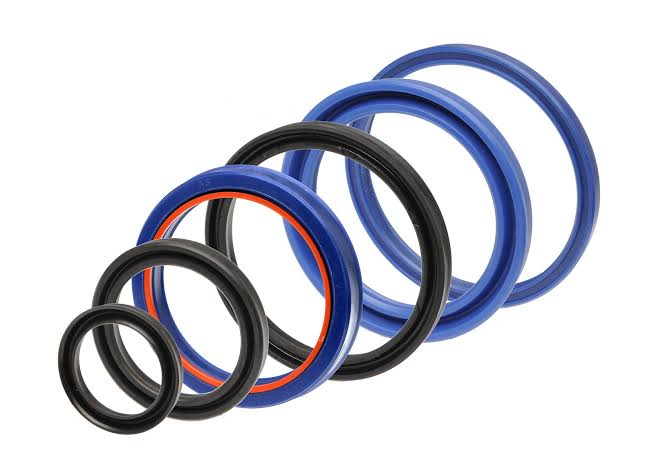

These are circular, ring-shaped mechanical seals that are often made of rubber or elastomeric materials. O-Rings are unique seals that can be used for both static and dynamic applications. They are inserted and compressed between two mating surfaces, creating a tight seal that stops fluid or gas leakage.

O-Rings are professionally designed to sit within the groove or housing of two components, with the ability to withstand extreme temperatures and pressures. These types of sealing have great resilience, flexibility, and high resistance to chemicals and varying temperature degrees, which makes them usable in hydraulic systems, pumps, valves, and many other mechanical assemblies.

Flat Washers

Plain washers are another name for flat washers. They are thin, flat discs with a central hole that are mainly used to distribute the load and offer a sealing function between the mating surface and bolts or nuts. Although the flat washer’s primary function is not sealing, or distributing pressure more evenly, it can help stop leakages and contamination by external elements. This minimizes the risk of surface damage or distortion.

Flat washers are different kinds of seals made of metal or non-metallic materials and are commonly used across various industries like construction, automotive, and machinery.

Different Kinds of Dynamic Seals

Dynamic seals are the direct opposite of static seals. They are best used when there is motion between the mating surfaces, which could be reciprocating, oscillating, or rotating movement. Discussed below are three basic types of dynamic seals, their features, and their applications.

Piston Seals

Piston seals are different types of seals specifically designed for reciprocating motion in hydraulic and pneumatic systems. They help prevent leakages and maintain pressure by positioning them between the piston and cylinder bore. These kinds of seals are engineered to withstand varying operating conditions, including high pressures.

Piston seals are typically made from materials like Polytetrafluoroethylene (PTFE), rubber, or Polyurethane (PU).

Rod Seals

Also known as shaft seals or oil seals, these types of sealing are inserted between the housing bore and the reciprocating rod or shaft to stop leakages and prevent external contamination. They are also often used in hydraulic and pneumatic cylinders.

Rod seals are configured to withstand radial loads, reciprocating movement, and exposure to varying fluids and temperatures. They can be designed to incorporate additional features like wipers or scrapers to boost their performance and extend their service life.

Rotary Seals

Also known as radial lip seals, these kinds of seals are commonly used for rotating shafts of equipment, such as pumps, gearboxes, and motors. They help prevent leakages and contamination ingress while ensuring optimal rotary movement.

Rotary seals are often made of rubber, elastomer, or PTFE materials to offer effective sealing, low friction, and resistance to wear. They come in various designs, including single-lip, double-lip, or labyrinth seal configurations, depending on the specific application requirements.

Get All Types of Seals from DCW

Dechengwang is a competent and reputable manufacturer with over 13 years of experience in making all types of seals, including static and dynamic seals. Using the best materials, the seals are built according to your application requirements. We also offer some value-added services like:

Strict Quality Control

Following ISO/IATF quality assurance approaches, the different kinds of seals are produced with high-grade materials and techniques, ensuring 100% traceability and consistency in mass production. After production, they are inspected severally to guarantee reliability.

Plenty of Customization Options

Thanks to our unrivaled experience working with high-performance materials and manufacturing all kinds of seals, we can provide you with a wide range of custom services. Send your demands and requirements to us; we will deliver them to you within the shortest time frame.

Conclusion

In summary, we’ve highlighted the different types of seals, discussing their features and applications. Basically, this influences the type of seal that will be used for any mechanical operation.

Would you like to get more professional guidance on the types of sealing? Feel free to contact us for a free quote and there’s no minimum order quantity or hidden setup charges attached.

For information on related topics, check here.