Applications: PTFE Bellows seals for valves

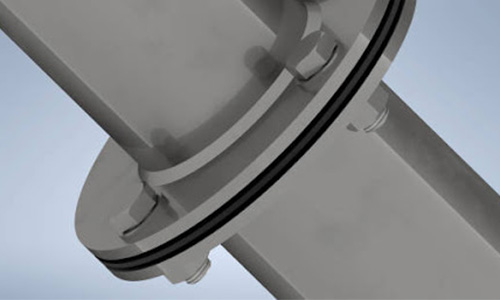

Bellows Mechanical Seal are a type of mechanical seal where the spring element is a bellows. They are a critical component in preventing fluid or gas

In the oil and gas industry, gaskets are essentials. They come in different types, sizes, materials and brands. It is important to make the right pick when shopping for them as compromising on size or quality can prove hazardous.

In the remaining part of this post, we will disclose to you the major types of gaskets used in the oil and gas industry, but before that, let’s define what a gasket is.

A Gasket is a sealing material used for covering or filling the intersection between two or more separable mechanical components of a flanged joint.

Gaskets after being properly compressed, become pressure-tight and are able to prevent leakages. They also stop the mechanical joints from breaking should they corrode after several years of operation.

The following are the types of gaskets in oil and gas:

Also called Ring gaskets or RTJ gaskets. Ring Type Joint gaskets come in Oval or octagonal shapes.

They provide very high gasket pressure to component joints with only a little bolt load; they are not pressure-actuated. Ring Type Joint’s usual applicable pressure is between 1,000 and 15,000 psi.

Ring gaskets are made of soft stainless materials. Due to this, there is usually a plastic deformation in the flange therefore it is necessary that they be replaced after usage. Failure to replace them is hazardous and can create any unsafe environment.

Because of its limitations, ring type joint gaskets are presently being phased out from high pressure and high-temperature uses. These days they are preferably replaced with the more stronger spiral wound gaskets that come with inner rings.

This is a semi-metallic gasket that controls compression and is more ideal for high pressure environments applications than Ring gaskets. They are one of the most common types of gaskets used in oil and gas industry

The temperatures Spiral Wound Gaskets can operate at ranges from –250 to 1,000°C. These gaskets are suitable for every pipe flange pressure rating.

Spiral Wound Gaskets come with inner rings that serve as a preventive measure against the buildup of solid materials between the bore of a pipe and inside diameter of the gasket. The rings are used in cases where the material of the gasket has the tendency to buckle inward.

Another function they perform is the protection of the system from damage by pieces of broken components.

To compress these gaskets, you need a bolt stress of 25,000 psi while the larger ones, 30,000 psi.

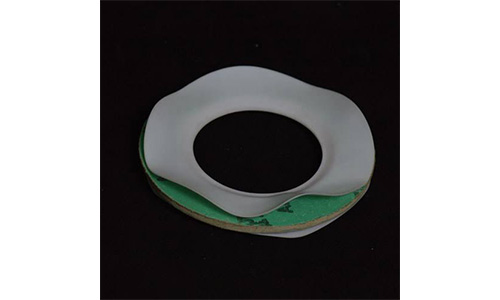

The envelope gasket is a type of gasket that benefits from the features of PTFE machined parts and provides strength for the core material. It is also known as the Double Jacketed Gasket. They either have PTFE on the outside of a Metal core of stainless steel or just plain double jacketed.

The main benefit of this type of gasket is that it has anti-corrosive qualities and is able to withstand high temperatures.

Also, envelope gaskets can not hold up well in high pressure applications as the flanges on the gasket tend to slip during fluctuations.

As the name implies, Non-Asbestos Sheet Material Gaskets are cut from sheet materials that contain no asbestos. Non-Asbestos Sheet Material Gaskets are often used in low pressure and low temperature environments.

This type of gasket has elastomeric properties and are commonly found with full-face flanges.

This can be seen on the market as Camprofile, Kammprofile, or even Grooved gaskets, it’s all the same material.

Kammprofile gaskets’ metal cores are bonded with a soft filler material on the two sides. These fillers are made with PTFE, graphite material or any other exotic materials.

These materials are very solid, making kammprofile gaskets to be used in high temperature and high pressure flanges. These gaskets are a great choice for radial sheer.

Spiral Wound Gaskets without an inner ring are semi-metallic gaskets that tolerates irregularities in the flange surface finish and offer good recovery tolerance.

These types of gaskets are not suitable for typical pipe flanges, at least not in high-pressure rated (600 pounds+) pipe flanges because they can buckle under high gasket stress.

When shopping for types of gaskets used in oil and gas, some key factors and parameters must be considered. They include:

Temperature is a very important parameter when choosing gaskets for your application. This is typically because oil and gas systems work at a continuous and varying temperature. When considering gaskets from ptfe components manufacturers, it is important to take note of any system temperature spikes and thermal cycling if there is any.

In the event of a temperature fluctuation, the gasket reacts to movements in the application related to contraction, expansion, and change in internal pressure.

Another parameter or determinant to consider when choosing a gasket for your application is fluid type.

You need to select the right type of gasket for the type of fluid that will be conveyed by the pipeline. Fluids usually require different types of gasket materials. This will make sure that the flanged joint is still able to operate in good conditions over a long period of time.

The ideal gasket must have enough flange pressure for compression to ensure that all openings are shut tight and remain unbroken.

Metal or aluminum is used in high-pressure applications like oil and gas production. Metallic gasket materials are available in oval and octagonal cross sections.

Non-metallic gaskets are usually in the form of PTFE seals, CNAF, Leather, or Graphite. They are often used in low pressure and low temperature applications with the exception of graphite gaskets, which can withstand temperatures of up to 460⁰C.

This is a combination of both metallic and non-metallic materials. Kammprofile and metal jacketed fall under this material group. Composite gaskets are cost-effective and can be used in different facilities although they need to be used with caution.

There are quite a number of gaskets available on the market, which is why making the right choice of gasket types in oil and gas facilities is quite tasking. Any mistake or misinformation can lead to colossal damage.

Do you want to find out more about the types of gaskets used in the oil and gas industry, feel free to contact us.

Bellows Mechanical Seal are a type of mechanical seal where the spring element is a bellows. They are a critical component in preventing fluid or gas

In the world of engineering and manufacturing, where precision and efficiency are paramount, the role of wear resistance plastic has evolved far beyond their conventional image.

PTFE is a versatile polymer with outstanding properties like chemical resistance, low friction coefficient (self-lubricating), non-stick nature, and excellent electrical insulation. However, it also has some