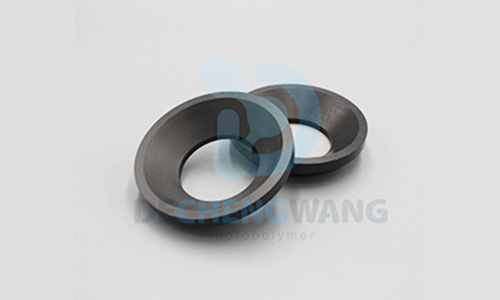

Applications: PTFE Bellows seals for valves

Bellows Mechanical Seal are a type of mechanical seal where the spring element is a bellows. They are a critical component in preventing fluid or gas

Recently, there has been a lot of interest in PVDF. This is because of the unique properties it has. PVDF polymers possess the strongest piezoelectric properties when compared to other commercially used types of polymers. These properties enhance the production of several high-purity, high-strength, and high-chemical products that are resistant to chemicals, temperature, and all other factors.

PVDF’s applications cut across several industries, including electrical, electronics, chemical, and energy industries. In recent years, this polymer has been dictating the wave of polymer manufacturing as many people are beginning to discover its intrinsic properties and capabilities.

To enlighten you more on PVDF material, in this post, we will disclose to you everything you need to know starting from what is PVDF material, its properties & performances, how it’s produced and processed, as well as its applications.

Before we begin, let’s first answer an obvious question, which is what does PVDF stand for? PVDF is a four-letter acronym that stands for Polyvinylidene Fluoride. It was first manufactured in 1969, and it’s also known as Polyvinylidene Difluoride, PVF2, or by its popular trade name, Kynar. It’s a polymer under the thermoplastic category.

Polyvinylidene Fluoride is one of the toughest, highly used purity, synthetic materials. It’s widely pronounced and selected for several applications for its improved resistance profile, mechanical & thermal strength, physical strength, magno-electric strength, and the ability to function in both solid and liquid coating forms. It has a service temperature of 150 degrees Celsius and a melting point that’s up to 175 degrees Celsius. This makes PVDF to be very cost-effective.

In making PVDF, fluorine (F) is used within the starting molecular base, which is why it’s referred to as a semi-crystalline fluoropolymer. The existence of fluorine in PVDF and its crystalline structure explains why it provides well-known superior service and tolerance ranges. This also makes PVDF polymers to have enhanced resilience against many chemical, mechanical, and biological stresses that other types of polymers can’t resist.

PVDF is usually available in five forms alpha, beta, gamma, delta, and epsilon. However, only three of them are common, and these are alpha, beta, and gamma.

The alpha form is non-polar, and it’s formed from melt crystallization during the melting process at any temperature.

For the beta form, the specimen is mechanically deformed through uniaxial or biaxial mechanical drawing below 70 degrees Celsius. Beta-form PVDFs are commonly used for piezoelectric applications.

The gamma form is a unique form that appears in specific circumstances. It can be produced via crystallization at temperatures that are up to the melting point of the alpha form. This is usually done through melt casting or solution casting.

Now, let’s discuss the properties and performance of PVDF.

As mentioned earlier, PVDF is a semi-crystalline polymer that’s 50% amorphous. It is formed in a pattern with a large percentage of the Vinylidene Fluoride (VDF) units linked from head to tail, while the smaller percentage are linked together from head to head.

Also, the chemical features of each fluoropolymer machining technique, including PVDF and PTFE machining techniques, vary with respect to a broad range of chemicals. When PVDF is mixed at high temperatures with organic solvents like animes and esters, they become strong enough to be used as corrosion-resistant glazing for chemical processing equipment.

PVDF also features great resistance to organic acids, alcohols, salt solutions, oxidants, aliphatic and aromatic hydrocarbons, and halogenated solvents.

Other general features include its excellent mechanical strength, resistance to UV rays, high purity, high abrasion resistance, excellent fire resistance, and low permeability to most gas & liquid.

When compared to other commercial fluoro-thermoplastics, PVDF is one of the plastics with the lowest melting point, however, it has the highest heat deflection temperature under load.

It has very low penetration values due to its high crystallinity and surface tension. PVDF also shows low permeability to gases and liquids. However, the degree of crystallinity and the crystalline component modification.

PVDF has a strong tensile modulus just as Ethylene Tetrafluoroethylene (ETFE) and Ethylene Chlorotrifluoroethylene (ECTFE). Although it has a lower impact strength. When they are used with HFP and CTFE, the flexibility and impact strength will improve, while the tensile modulus reduces.

Also, PVDF is resistant to flame. It’s non-flammable and it wouldn’t even drip. It is self-extinguishing and offers a decent level of UC resistance.

PVDF material has the capability to withstand heat. This is one of the advantages they have over other polymers. PVDF has the ability to resist heat up to 375 degrees Celsius without any indication of thermal or oxidative breakdown.

Amongst the properties of PVDF polymers are high dielectric strength and dissolution factor. Although they have a little bit of poor electrical features, which makes it easier to use the polymers in films with piezoelectric action.

The films are usually extracted from the PVDF polymers when they are in their Beta-form. The surfaces of both films will be glittering and subjected to high voltage, making them to be permanently polarized. When stretched or compressed at their melting point temperature, they produce current.

Material Data Sheet

General Features | Excellent mechanical strength Resistance to UV radiation | High purity Excellent chemical resistance | High abrasion resistance Excellent fire resistance | Low permeability to most gas and liquid High temperature capabilities |

|---|---|---|---|---|

Physical Properties | Density (specific gravity) Water absorption (Max.) 24 hours Flammability | ASTM D-638 ASTM D-570 | g/cm3 (gm/cc) % – | 1.75 – 1.80 <0.04 V-0 |

Mechanical Properties | Tensile strength Elongation of break Tensile modulus Hardness shore | ASTM D-638 ASTM D-638 ASTM D-638 ASTM D-2240 | MPa % GPa Shore D | 50 10 – 50 Equal to or more than 1.8 Equal to or more than 75 |

Thermal Properties | Peak melting temperature Specific heat capacity (23 degrees celsius) Thermal conductivity (23 degrees celsius) Continuous use temperature Oxygen index (Loi) | ASTM D-638 DSC ASTM E-1530 – ASTM D-2863 | oC kJ kg-1 oC-1 W/mK oC % | 170 -175 1.2 0.2 150 44 |

Electrical Properties | Dielectric strength (0.255 mm thick) Surface Resistivity Volume Resistivity | ASTM D-149 ASTM D-258 ASTM D-257 | Kv/mm ohm ohm cm | 20 – 25 >1014 >1014 |

PVDF is initially made as a raw resin from a chemical synthesis reaction, known as polymerization. But the polymerization of PVDF differs because of its required production parameters, operating catalyst, and most importantly, the monomer (the starting base).

In the production of PVDF, the monomer form, which is the Vinylidene Fluoride (VDF) , is polymerized. In doing this, the single VDF units are combined end-to-end to form a long network molecule, which is known as Polyvinylidene Fluoride (PVDF).

VDF is the reactive outcome of additional chemical processing of waste materials from refining flammable gases and natural oils. To make PVDF, the monomer (VDF) undergoes free radical polymerization that happens when they are heated at pressures of 300 atm and temperatures up to 150 degrees Celsius. Just like other types of thermoplastics, polymerized PVDF can be recycled.

PVDF polymers are produced into parts and coatings by using two basic methods. The first is the melt casting method and the second is the solution-processed method (which is divided into solution casting, spin coating, and film casting). These methods are explained below.

Melt casting: Basically, it involves heating the polymer until it melts. Then, the molten polymer is poured into a mold to form the desired shape as it cools and hardens.

Solution casting: To form the appropriate porous polymer membrane the polymer is dissolved into a suitable solution. The solubility of PVDF is influenced by the polarity, temperature, and molecular weight of the solvent.

Spin coating: This method is used to produce thin films from the higher beta-form. Here, the films are stretched and put under high pressure or an electric field to make piezoelectric thin film items.

Film casting: This method is sometimes referred to as film extrusion. It involves the use of a customized extrusion procedure where the polymer is fabricated into uniform high-quality films of thin sheets.

There are different grades and forms of PVDF polymers, including pallets and powders. They can be easily processed by common traditional methods like machining, compression, and transfer molding, as well as the two most common traditional processing methods – injection molding and extrusion.

Drying the PVDF before processing begins does not really matter, although you will have to do so in some cases. However, while doing so, you have to be careful in order to eliminate “hang-up” parts where molten plastic can gather and thermally decompose if residence time is too much. The processing temperature is usually between 190 degrees Celsius to 290 degrees Celsius.

Now, let’s quickly examine the two most common processing methods – injection molding and extrusion.

Melting processing temperature is between 200 degrees Celsius to 270 degrees Celsius

Mold temperature should be within the range of 50 degrees Celsius and 95 degrees Celsius

An accurate mold design must be used. The high melting viscosity of PVDF necessitates that the right mold is used in injection molding

Shrinkage of 3 to 4 percent of injected molded pieces should be factored in during conception

The melting temperature should be between 230 degrees Celsius to 290 degrees Celsius

Attention should be given to the elimination of dead spots where degradation of the molten resin can start

No additional aid, lubricant, or heat stabilizer is needed to remove the PVDF

Now, let’s answer the question: what is PVDF used for? As stated above, PVDF has a long range of capabilities, strengths, and increased operational parameters. The polymer is often preferred for use across several applications. Some of them are stated below.

Thanks to its heat resistance and insulation capabilities, PVDF is used as plumbing for product synthesis operations, energy generation reactors, and electrical cable coatings & wiring.

PVDF is used in the chemical sector for its chemical tolerance and minimal permeability.

PVDF is used to handle harsh liquids and gaseous products, such as sulfuric, nitric, and hydrochloric acid, as well as compounds like halogenated, aliphatic, and aromatic solvents. Their uses also extend to refined and unrefined products, oils, and combustible fuels.

The abrasion resistance feature and purity profile of PVDF make it applicable in pharmacology and medical settings. They are also used for ultrapure water and for extended contact time with consumables in food-grade production.

Thanks to its thermal tolerance, non-toxic status, sunlight resistance, nuclear radiation, and microbiological growth, PVDF is frequently used for many plumbing functions.

PVDF complies with American Society for Testing and Materials regulations for 25/50 flame and smoke speed ratings, making it suitable for plenum applications in plumbing.

Used as an additive in paints, as well as a weather-shield in coatings for roofs and other equipment that are exposed to harsh weather.

PVDF possesses good corrosion properties, making it useful in sectors like oil & gas, marine, automotive, and petrochemicals for manufacturing components like gaskets, linings, and seals (PTFE seals are also suitable for this purpose).

Thanks to its heat and chemical resistance, PVDF is applicable in making separators for lithium-ion batteries. This function is set to increase in the coming years as the market for electric mobility is constantly growing.

The transducers in piezoelectric films are extremely sensitive. With PVDF, they can be molded into malleable, rigid, and lightweight geometries that are useful in unique applications.

Specialty monofilament fishing lines that are made of PVDF are provided as fluorocarbon alternatives to nylon monofilament. PVDF has a tougher surface, making it resistant to fish teeth and abrasion. Even fishes with sharp eyes will have a hard time identifying the line as it has a lower optical density than nylon. In addition, because it is denser than nylon, it sinks more quickly toward fish.

These are a few of the industrial applications of PVDF.

Due to PVDF’s combination of flexibility, low weight, thermal conductivity, strong chemical resistance, and heat resistance, it’s often used as insulation on electrical wires. Almost all the narrow 30-gauge wires used in printed circuit board networks and wire wrap circuit assembly are insulated with PVDF. In this application, the wire is commonly called after its brand name, “Kynar wire.”

PVDF possesses piezoelectric capabilities, which make it useful in manufacturing lightweight acoustic transducers, cost-effective strain gauges, and tactile sensor arrays. This outstanding thermoplastic is also used for

Because of its resistance to corrosion and abrasion, PVDF is used in the petrochemical industry to manufacture gaskets, as well as other equipment like seals and linings. It’s also used for energy-consuming, automotive, and military aircraft purposes.

PVDF is also used for making chemical equipment, such as pumps, valves, and pipes. It is also used to make flexible and heat-shrinkage tubes that are used in high purity water systems, chemical pipelines, and fuel lines for automobiles, among other applications. In addition, PVDF is immensely used as a liner for valves and pipes.

In the biomedical sciences, PVDF is utilized as an artificial membrane in immunoblotting over which proteins are transferred using electricity and it typically has pore sizes of 0.22 or 0.45 micrometers. Since PVDF is solvent-resistant, it becomes easier for these membranes to be removed and reused to check out other proteins. PVDF membranes can be used in other applications as a component of a membrane filtration device, usually in the form of a wheel or syringe filter.

Practically all the properties of the PVDF material (heat resistance, low protein binding, resistance to chemical corrosion, etc) makes it valuable in the making of medications as a sterilizing filter. It also functions as a filter that’s used to make samples for analytical processes, where a small quantity of particulate matter can destroy sensitive and expensive equipment.

PVDF transducers have the benefit of being compliant for structural integration than other transducers like piezoceramic transducers. They are also more dynamically suited for modal testing than semiconductor piezoelectric transducers.

For these reasons and cost-effectiveness, PVDF Is currently used and forecasted as a future structural-health monitoring method.

PVDF and PTFE are two important industrial polymer materials that are made up of a large number of monomer units. They are arguably the best two polymers on the market. While they seem very similar in their functions, they have some differences.

In the next series of paragraphs, we will do justice to their differences. For easier understanding, let’s quickly give a recap of what PVDF is, and then we dive into PTFE, before going to the differences between both of them.

PVDF stands for Polyvinylidene Fluoride, which is a highly non-reactive thermoplastic material. It’s made from the polymerization of several units of its monomer, Vinylidene Difluoride (VDF). PVDF has outstanding properties, such as 50% crystallinity, high purity, low glass transition temperature, high resistance to solvents, acids, hydrocarbons, esters, ketones, caustics, and all other chemical substances. It also has piezoelectric characteristics, which come from mechanical elongation.

PVDF polymers are useful for producing different forms of sheets, tubes, films, plates, and piping products, as well as insulation for wires.

Despite all these excellent properties, PTFE machined parts are a little bit more reliable than PVDF parts for some applications.

PTFE, which is commonly called “Teflon” stands for Polytetra Fluoroethylene. It’s made up through a process called, “free-radical polymerization,” which is done by polymerizing several units of its monomer, Tetrafluoroethylene. PTFE has outstanding properties, such as high strength, flexibility, and toughness, with self-lubricating features. Just like PVDF, it’s resistant to chemicals and other foreign elements.

PTFE is regarded as a non-reactive and useful polymer for non-stick coatings, and this is due to the carbon and fluorine bond that it’s made of. Some PTFE applications include the manufacturing of pipes and containers, as well as lubricants to reduce friction.

Asides the points stated in their definitions above, the major difference between PVDF and PTFE is that PVDF has a lower density when compared to PTFE.

This is a tabular format of the differences between these two important industrial polymers.

PVDF | PFTE | |

Full Meaning | Polyvinylidene Fluoride | Polytetrafluoroethylene |

Repeating Unit | (C2H4)n | (CH2F2)n |

Production | Polymerization of vinylidene difluoride | Free-radical polymerization |

Density | Relatively low | Relatively high |

Applications | Manufacturing of various types of sheets, tubes, films, and piping products, as well as insulator for premium wires | Manufacturing of pipes and containers, as well as non-stick coatings |

Dechengwang provides a wide range of PVDF parts that possess great properties and performance, such as high purity & low extractability, nuclear radiation resistance, excellent creep resistance, low permeability, resistance to chemicals & ultraviolet rays, and wide service temperature ranges. We make custom PVDF parts for all industries and applications like electrical, healthcare, food & beverage, and chemical.

Dechengwang stands out with outstanding manufacturing capabilities as we deal with a wide range of materials, including PVDF, PTFE, PEEK, PFA, and PCTFE. Amongst all other PVDF and PTFE component manufacturers, we are highly rated for providing other unique products like bellows, seals, insulators, labware, bushings, ball valve seats, tubes, rods, films, and sheets.

PVDF, which can be called by its trade name, Kynar is a stable, non-reactive, 50% crystalline polymer that’s majorly used for high purity chemical-resistant, and piezoelectric applications. When compared to other polymers, it’s highly preferred as it functions in many cases where others are vulnerable.

PVDF polymers contain many properties that make them to be considered superior to comparative polymers like PVC and polyethylene. However, PTFE polymers, which also contain a variety of outstanding properties are preferable in some cases.

Bellows Mechanical Seal are a type of mechanical seal where the spring element is a bellows. They are a critical component in preventing fluid or gas

In the world of engineering and manufacturing, where precision and efficiency are paramount, the role of wear resistance plastic has evolved far beyond their conventional image.

PTFE is a versatile polymer with outstanding properties like chemical resistance, low friction coefficient (self-lubricating), non-stick nature, and excellent electrical insulation. However, it also has some