The smooth operation of several critical vehicle parts largely depends on automotive sealing. An automotive seal acts as a reliable barrier to protect against harmful leaks, pollutants, and pressure fluctuations in different systems within the vehicle.

Understanding automotive sealing can help you better comprehend the complex systems that maintain cars functioning smoothly. Without any further ado, let’s begin exploring the world of car oil seals and their importance in the functionality of a car.

What Is Automotive Sealing?

As the name suggests, automotive sealing is a process of providing sealing benefits to various car parts. This process ensures no leaks in any car parts, further guaranteeing the proper operation of automotive systems. To successfully carry out this process, specialist sealing materials are used, including gaskets, O-rings, seals, and sealants.

Automotive sealing is essential for preserving the performance and reliability of many car systems, such as engines, gearboxes, exhaust systems, fuel systems, cooling systems, and more.

Materials For Automotive Seals

When selecting the materials for sealing automotive, you must ensure that the material you have picked should be an outstanding resistor and is compatible with automotive fluids. The top five materials for automotive seals are examined in further detail below.

Fluorocarbon

Fluorocarbon is a remarkable material that is ideal for creating o-rings. It has certain excellent characteristics that make it effective in various applications.

One crucial point is that some varieties of fluorocarbon can withstand the toxins included in modern transmission fluids. Fluorocarbons can seal against these oils’ amines, which are often present and can harm other materials.

Benefits of Fluorocarbons:

- It is capable of handling ethanol and methanol, as well as high-octane gasoline mixes and fuels with extra oxygen.

- Because they can withstand swelling, they maintain their form and function effectively in these fuels.

- Ideal for ethanol or methanol-laced fuel sealing applications.

- Fluorocarbons can withstand temperatures between -13°F and +446°F.

Nitrile

Nitrile, sometimes called Buna-N, is a highly economical material extensively used in various sectors. Nitrile is a fantastic material for manufacturing seals automotive in the automobile industry since it can successfully seal against petroleum-based fluids and fuels. It can also manage standard hydraulic fluids and silicone greases used in automobiles.

Benefits of Nitrile:

- Standard nitrile compounds are ideal for hot and cold situations since they can withstand temperatures between -40°F and +257°F.

- They offer an effective barrier to stop leaks and guarantee the engine’s accurate operation.

- Fluids like silicone greases and hydraulic fluids can be successfully contained by nitrile seals, ensuring the performance and integrity of the system.

- For automotive sealing applications, nitrile demonstrates strong resistance to wear, abrasion, and tearing.

Perfluoroelastomer

Due to its exceptional resistance to deterioration from harsh fluids and gases, perfluoroelastomer, also known as FFKM, is a specialist material often used in automotive applications. FFKM is resistant to almost all chemical attacks, including those from lubricants, fuels, and additives used in automobiles.

Benefits of Perfluoroelastomer:

- It retains its ability to seal against abrasive vehicle lubricants, fuels, and other additives without degrading or losing that ability.

- The sealing effectiveness of FFKM seals is unaffected by temperatures between -13°F and +600°F.

Polytetrafluoroethylene

Polytetrafluoroethylene (PTFE) is a highly versatile material in various seal automotive applications. Its special qualities make it a great option for sealing parts in automotive systems, delivering reliable performance and advantages. Choose a reliable PTFE supplier to get the most out of these seals.

Benefits of Polytetrafluoroethylene:

- PTFE has remarkable resistance to various automotive fluids such as lubricants, fuels, and hydraulic fluids.

- In addition to enhancing overall performance and durability, the low friction property helps to reduce wear and increase the lifespan of automobile seals.

- From extremely low to extremely high temperatures, PTFE can withstand any temperature.

- As most compounds don’t react with PTFE seals auto, chemical reactions, and fluid pollution are minimized.

Fluorosilicone

Although fluoro silicone is often used in aerospace applications, it also offers excellent qualities for manufacturing seals auto in the automobile sector. It is gaining popularity across a range of businesses.

Benefits of Fluorosilicone:

- The common varieties of fluoro silicone are unaffected by temperatures between -75°F and +400°F.

- When it comes to sealing against liquids like gasoline and oil, fluoro silicone excels.

- For extended periods, fluoro silicone can be exposed to ozone, sunlight, and air.

Types Of Car Oil Seals

Car oil seals play a crucial role in the automotive industry by maintaining the correct containment and circulation of lubricating oil inside different parts.

O-Rings Seals

O-rings are an essential part of the automobile sector. They form a solid seal between two surfaces, keeping fluids like oil well contained and preventing leaks. O-rings and seals auto can be made from several materials to fulfill different performance requirements.

Material Used: For any application to operate at its best, careful material selection is essential. Nitrile, EPDM, Silicone, and Fluorocarbon are common materials for creating O-Rings.

Application: O-rings are used in many vehicle systems to make tight seals and stop leaks. The most typical uses are air conditioning systems, lubrication circuits, and braking systems.

Lathe Cut Gasket

A special kind of gasket used for sealing in the automobile sector is called a lathe-cut gasket. It is made using a lathe machine, which cuts the gasket material into the proper form and size, hence the name “lathe cut” gasket. This manufacturing procedure enables precise and accurate dimensioning, enabling a good fit between mating surfaces.

Lathe-cut gaskets are widely used due to their superior sealing abilities and resilience to heat, oil, and other vehicle fluids. These gaskets are essential for sealing vital auto parts, stopping leaks, and guaranteeing the efficient operation of numerous systems in cars.

Materials Used: Depending on the specifications of the particular application, a number of materials are generally used to create lathe-cut gaskets. Rubber, cork, metal, and fiber are often used materials.

Application: To avoid fluid leaks and ensure peak engine performance, they are often found in engine parts, including cylinder heads, valve covers, oil pans, and water pumps.

Additionally, lathe-cut gaskets are used in cooling systems, transmission and gearbox assemblies, fuel systems, exhaust systems, and fuel systems to provide a tight seal, stop leaks, and preserve the effectiveness of these systems.

Lip Seals

Elastomeric seals in the form of rings called lip seals are intended to be used around shafts. The presence of a lip characterizes them and is also referred to as rotary seals. Lip seals are not ring-like objects. Instead, they have a lip. They may achieve a tight fit around shafts owing to this lip.

Materials Used: Car oil lip seals are widely available in the market and are made using various materials. Nitrile rubber, metal, viton, silicon, and neoprene are a few materials used to create car oil lip seals.

Application: In the automobile sector, a lip seal performs several crucial tasks.

First, it serves as a physical barrier that keeps the lubricating oil where it belongs. This is essential to make sure the oil stays where it should be, guarding against any potential damage or malfunction.

Second, even under high pressure inside the oil system, the lip seal is crucial in avoiding oil leakage. This preserves the system’s integrity, preventing lubricant loss and ensuring peak performance.

The lip seal also serves as a protective barrier by preventing dirt, pollution, and other external substances from entering the system that contains the lubricating oil. It protects against any damage or interference these outside sources produce by effectively closing off the system.

Benefits Of Automotive Seals

In a variety of automotive applications, automotive seals provide numerous crucial advantages. The principal benefits of automobile seals include:

Prevent Liquid Leakages

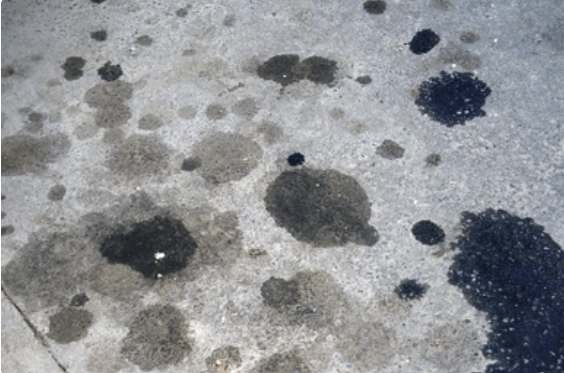

Preventing liquid leaks is one of the main purposes of automotive seals. No matter what kind of liquid they are—oil, coolant, hydraulic fluid, or another—seals establish a barrier that keeps them contained in those locations.

Automotive seals assist in preserving correct fluid levels, avoiding environmental pollution, and guaranteeing the efficient operation of various systems by successfully sealing off potential leakage sites.

Separate Liquids And Gases

Keeping liquids and gases separate throughout various parts and systems is another critical function of automotive seals. For instance, seals are used to keep coolant and oil separate in engines. This prevents cross-contamination and ensures that each fluid fulfills its original purpose to the fullest extent possible.

Similar to how seals in the vehicle’s exhaust system help in separating exhaust gases from other parts, they also enhance the vehicle’s effectiveness and safety.

Help Protect Bearings

Bearings are essential parts of automobile systems because they support rotating shafts and lower friction. Automotive seals provide a barrier against impurities like dirt, dust, water, and other foreign objects, hence assisting in protecting these bearings.

Seals help to increase the lifespan of bearings, lessen wear and tear, and ensure optimum performance and dependability by keeping these pollutants from accessing the bearing region.

Keep Dust And Contaminants Away

Automotive seals prevent gaps from being left for introducing foreign elements; they seal everything together. Because of the introduction of these foreign substances, the fluids will either be contaminated or, even worse; they could react to the toxins.

You can be confident that your fluid won’t be polluted in any way by using the appropriate kind of oil seal.

Where Seals Make All The Difference In Your Car?

Various automobile parts require seals to perform reliably. In the section below, you will learn about the parts that function optimally because of the automotive seal.

Engine

Any car’s engine is its most crucial component. The reliable running of the car’s engine depends on seals. Seals are used throughout the engine to keep oil where it belongs and to shield the engine’s internal components from dirt and debris, both of which are common on the road.

Interior Cabin Systems

Automotive seals are essential for a peaceful and comfortable environment within the cabin. Seals are used in doors, windows, sunroofs, and trunks to keep out noise, dust, water, and other outside factors.

Fuel Tank Systems

Gasoline tank tops, gasoline filler necks, fuel pump assemblies, and fuel injectors need seals to provide a tight-fitting, leak-free system that ensures adequate fuel containment and flow.

Transmission

A transmission has many gears, and each must be kept lubricated. Seals can help in this situation. Numerous seals throughout the gearbox keep oil within, allowing the system to develop pressure that, in turn, aids in shifting the transmission through the gears.

Batteries

Battery systems require automotive seals to stop electrolyte leakage, which might be damaging, caustic, and even fatal. Seals aid in preserving a tight, leak-free casing for the battery, assuring optimal operation and shielding neighboring components from damage or contamination.

Brakes

Seals in the anti-lock valves of modern braking systems prevent skidding. The brake valve has seals that transmit the pedal motion when the car comes to a complete stop.

DriveTrain And Exhaust System

Seals are used in the drivetrain’s axles, differential housings, and transmission cases to stop fluid or lubricant leakage.

Seals in the exhaust system guarantee that connections between parts are properly sealed, limiting exhaust gas leaks, attenuating noise, and ensuring the effectiveness of emissions control systems.

4 Reasons For Oil Seal Failure And Their Solutions

Various reasons lead to the failure of car oil seals, and these failures can lead to major problems in a car. Preventing these failures will help the car parts to perform optimally and efficiently. In the section below, you can find the reasons for oil seal failure and how to prevent them.

Resistance To Chemical Attack

Chemicals of various kinds are introduced to the oil seals. Seals made of Natural Rubber, Polyisoprene or Polyurethane may show several signs of incompatibility with the chemical composition of oil, such as breaking down, blisters, discoloration, and changes in toughness levels.

Solution: For the seal to be compatible with chemicals, choosing the proper sealing material is crucial. Chemical attacks are caused by this incompatibility, which intensifies at high temperatures or pressures. Therefore, before selecting the seal material for your application, ensure it is compatible.

Relief Of Lip Deformation

Another common cause that leads to oil seal failure is lip deformation. This could happen due to high heat, high pressure, or poor installation. Oil leaks can be caused by deformed lips because they function poorly while sealing.

Solution: To solve this problem, proper heat dissipation and cooling techniques should be used, making sure that the operating temperature stays within the seal’s tolerance range. Also, proper installation methods should be paid attention to, including ensuring the seal is correctly aligned and not overstretching or distorting it when installing.

Control Over Out-Gassing

The term “out-gassing” describes the emission of vapors or gases from the sealant. These gases occasionally have the ability to cause the seal to become less elastic and break sooner.

Solution: It’s essential to choose the right seal material to reduce out-gassing. It’s crucial to choose materials with low volatility to reduce out-gassing. The risk of contaminating or interfering with fragile equipment or processes is significantly reduced by these materials’ low inclination to produce gases or vapors.

Additionally, certain seal materials are made especially for situations involving high temperatures. The formulation of these materials prevents substantial out-gassing or deterioration, even at high temperatures.

Avoidance Of Physical Damage

During handling, installation, or use, oil seals can suffer damage. Sharp items, high-pressure, or abrasive pollutants may be the culprits.

Solution: To avoid such damages, you must ensure proper care is performed. Physical damages such as cuts or rips from sharp equipment or rough surfaces can be prevented if proper care is assured.

Routine maintenance and inspections are crucial to identify and resolve any early indications of physical damage and stop future deterioration.

Factors To Consider When Choosing Your Automotive Sealing

When you are choosing an oil seal for caras, ensure to consider the following given factors. These factors will ensure that the oil seal you have used will perform reliably for a long time.

Environment

The choice of material for oil seals for cars is heavily influenced by the environment to which the sealing will be subjected. Think about things like exposure to high or low temperatures, humidity, chemicals, UV rays, and hazardous pollutants.

Material like polytetrafluoroethylene (PTFE) has been created to meet these challenges head-on, with each material holding its own special qualities to triumph over environmental risks.

Temperature

The most important factor to consider is making sure that the seal’s material temperature is in line with the temperature of the surrounding environment. The sealing lip may harden as a result of the excessive warmth, which may eventually result in fractures.

When attempting to reduce the hazards associated with temperature-related situations, choosing seal materials able to withstand the expected temperature range is crucial. Various materials, such as polytetrafluoroethylene (PTFE) and nitrile rubber, exhibit distinct temperature tolerances and are designed particularly to work best within specific temperature brackets.

Operating Pressure Of Oil Seals

Another important thing to consider is the operational pressure the oil seals will put on. Furthermore, considerations like pressure cycling or spikes should be addressed when choosing a material and type that can withstand dynamic pressure circumstances.

O-rings and lip seals are often used for sealing purposes and are suited for a variety of pressures, including both static and dynamic pressure settings.

Shaft Speed

Another crucial factor is the shaft’s rotating speed, which the oil seal for cars will be in contact with. High shaft speeds can cause heat and friction, impairing the sealing material’s efficacy. To avoid excessive wear, heat buildup, or early failure, ensure the seal material you choose is suitable for the expected shaft speed.

DCW: An Automotive Sealing That Satisfies You

DCW is a reputable manufacturer of fluoropolymer products, including seals. Seals are used to halt leaks precisely, increase the lifespan of automobile parts, and ensure safety. We provide many kinds of oil seals for cars, which are used to make them run more smoothly.

Professional Machining Advice

DCW manufactures PTFE automobile seals and gives its clients expert machining guidance. This involves using our experience and in-depth understanding of the sector to help clients choose the materials, designs, and machining methods most suited to their unique sealing needs. DCW assists clients in optimizing their seal designs and achieving the optimum sealing solutions by offering professional advice and considering factors such as application, operating circumstances, and performance requirements.

Third-Party Inspection Support

We at DCW are devoted to manufacturing automobile seals to the highest possible quality standards. We go above and beyond by providing third-party quality inspection support to guarantee our products’ exceptional quality.

We can guarantee our clients that our seals have passed an independent evaluation of their function and quality thanks to third-party evaluations. This additional level of inspection strengthens our dedication to providing trustworthy and high-caliber seals. Additionally, it exemplifies our commitment to openness and responsibility throughout the production process.

Traceability Of Each Batch

At DCW, we are aware of how crucial traceability is in the creation of automobile seals. We’ve established a reliable system that ensures that every step of the production process, material used, and quality control measure for every batch of seals manufactured is meticulously tracked and documented.

Our traceability system enables us to keep a thorough record of each step taken in manufacturing our seals. Each step of the manufacturing process (from acquiring resources to packing) is recorded for specific information. We are able to respond quickly to any problems or difficulties that could develop during or after manufacturing because of this degree of traceability.

Conclusion

Anyone working in the automobile business has to grasp the basics of automotive sealing. Understanding the significance of seals and their function in preserving efficiency, performance, and safety is crucial.

It is important to select a reputed and trusted company when getting automobile seals. DCW is the best manufacturer of fluorocarbon products that offers remarkable automotive seals. DCW is committed to providing automobile seals of the highest grade.

Our seals are made using quality materials, go through a strict quality inspection, follow industry standards, and guarantee the best performance and durability. Choose smartly and work with DCW for automotive sealing requirements. To discuss your needs, get specialized support, and enjoy the advantages of dealing with a reliable automotive sealing manufacturer, contact us right now.