In our previous blog post, we introduced Glass filled PTFE materials. Today, we will shift our focus and discuss another type of filler: carbon. carbon filled PTFE.

PTFE, one of the most widely use high performance plastic materials, boasts a wide range of advantages such as heat resistance, chemical resistance, insulation, non-stick properties, and low friction. Its applications span across diverse fields, including semiconductor devices, chemical plants, automobiles, office equipment, and home applications. Nonetheless, PTFE faces challenges in terms of insufficient abrasion resistance and creep resistance. The addition of a different material, namely, filler, can alleviate these problems.

What is carbon filled PTFE?

Carbon filled PTFE is infused PTFE with carbon/graphite to deliver the highest quality anti-static and wear resistant performance.

Carbon is one of the widely distributed elements in nature. With our deepening understanding of the physical and chemical properties of carbon, as well as the development needs of modern industry, many carbon products have become indispensable basic materials in modern industry. These include synthetic graphite (electrodes), carbon black (tires, ink), and carbon (graphite) fibers (aerospace, sports equipment), among others. In our topic, mainly focusing on carbon coke and graphite.

Carbon is a highly use filler for PTFE. it reduces creep, increase hardness and provides electrically and thermal conductivity, especially for high-speed applications. Carbon filled PTFE compounds, when combine with additional small percent of graphite, pretty much to like 2-3% percentage. will have a significant effect of wear performance. carbon graphite PTFE compounds performs extremely well also in dry running applications, where this application is non-lubricated.

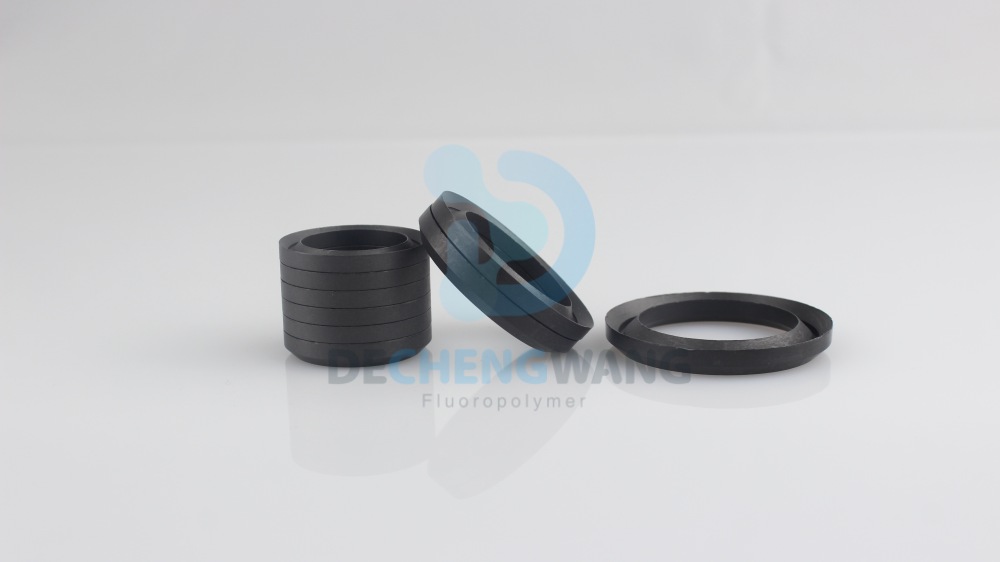

Carbon filled PTFE compounds are good choice for seals rings in dynamic high-pressure applications, carbon improves the thermal expansion properties of PTFE material. It also provides good thermal conductivity, low creep ability, and electrically conductive.

What does carbon improved?

PTFE, in conjunction with carbon, exhibits exceptional mechanical and wear characteristics, offers good thermal conductivity, low permeability, and possesses electrical conductivity. The distinctive properties are outlined below:

- Good cold flow reduction.

Carbon-filled PTFE demonstrates a notable reduction in cold flow, also known as creep, which refers to the material’s tendency to slowly deform or flow over time under constant stress, even at low temperatures. The incorporation of carbon particles into the PTFE matrix reinforces the material, limiting the movement of polymer chains and minimizing the risk of deformation under stress or pressure.

- Good wear resistance.

Carbon-filled PTFE exhibits excellent wear resistance properties, making it highly suitable for applications that involve sliding or rubbing surfaces. The addition of carbon particles enhances the material’s ability to withstand friction and abrasive forces, thereby reducing wear and extending the component’s lifespan.

- Good thermal conductivity.

Carbon-filled PTFE offers good thermal conductivity, allowing it to efficiently transfer heat across the material. This property is beneficial in applications where effective heat dissipation is essential, as it helps to prevent the buildup of excessive heat and maintain optimal operating conditions.

- Electrically conductive.

The incorporation of carbon particles imparts electrical conductivity to PTFE, making it an excellent choice for applications that require electrical dissipation or grounding.

- Excellent chemical resistance.

Carbon-filled PTFE possesses excellent resistance to a wide range of chemicals, including acids, bases, solvents, and corrosive substances. This exceptional chemical resistance ensures that the material remains stable and unaffected when exposed to harsh environments or aggressive chemicals, making it ideal for applications in chemical processing, oil and gas, and similar industries.

- Low tool wear during machining.

When machining carbon-filled PTFE, it offers the advantage of low tool wear. The material’s composition and properties enable it to be machined with relative ease, resulting in reduced tool wear and extended tool life. This benefit contributes to cost savings and improved machining efficiency.

- Protects sliding face, even without dry lubricants.

Carbon-filled PTFE exhibits self-lubricating properties, allowing it to provide effective lubrication and protection to the sliding partner even in the absence of additional dry lubricants. This characteristic minimizes friction, reduces wear on mating surfaces, and enhances the overall performance and durability of the system.

While carbon-filled PTFE offers many advantages, it also has some limitations or weaknesses to consider:

- Conductivity limitations: While carbon-filled PTFE is electrically conductive, but this might be a problem for application which needs to be insulate.

- Low elongation: High percentage filled means low elongation.

| Filler | Typical filler content by weight | Effects of the filler | Weakness of the filler |

| Carbon | 25% | Good cold flow reduction. Good wear resistance. Good thermal conductivity. Electrically conductive. Excellent chemical resistance. Low tool wear during machining. Protects sliding face, even without dry lubricants. | Conductivity limitations Low elongation |

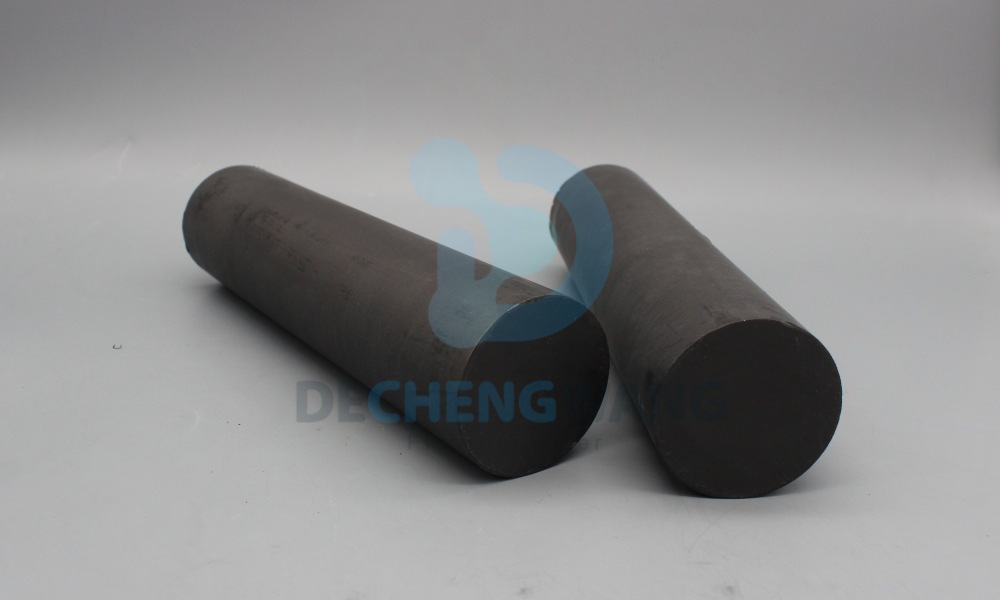

carbon filled PTFE data sheet

Carbon-filled PTFE compositions typically consist of 75% virgin PTFE combined with 25% carbon powder by weight. However, it’s important to note that the type and percentage of carbon incorporated into PTFE can vary significantly and have a crucial impact on the material’s performance. The specific percentage of carbon used will result in distinct material properties and performance characteristics.

| Filler | Filler content | Specific gravity | Tensile strength (cross direction) | Elongation (Cross direction) | Hardness | Shrinkage rate | Other possible combinations |

| – | – | ASTM D4894 | ASTM D4894 | ASTM D4894 | Needle type | Internal Method | – |

| – | % | – | Mpa | % | Shore D | % | – |

| Non-filler | – | 2.17 | 31 | 310 | 57 | 3.0 | – |

| Hard Carbon | 25 | 2.10 | Min.15 | Min.90 | 63 | 2.5 | Graphite |

| Soft Carbon | 25 | 2.35 | 18 | 190 | 63 | 2.6 | Graphite |

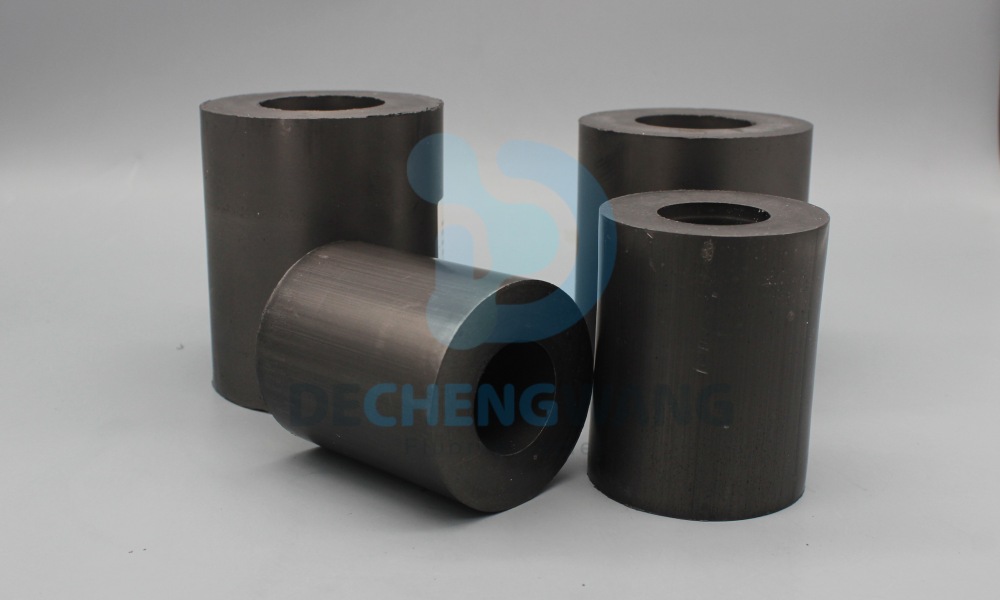

The main application.

Carbon filled PTFE finds a wide range of applications across various industries due to its unique properties and performance advantages. Here are some common applications where is utilized:

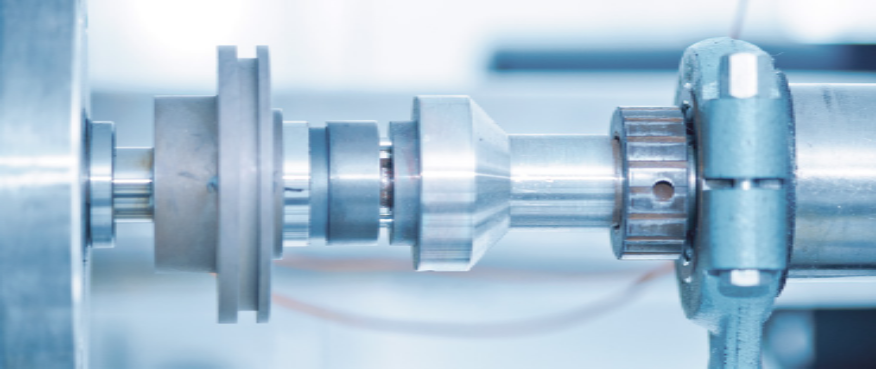

- HTHP application

- Oil & Gas valves

- Rotary seals

- Dynamic water applications

- Rider and piston rings of air compressor

- Shaft bearing in high speed chemical pumps

- Ideal for water applications and recommended for medium and high loads

- Compressor ring, V-ring, and packing

- Recommended for dry running with a low to moderate load

- A wide variety of seals and bushings

DCW is one of the few PTFE manufactures to be fully integrated, having the capabilities to produce a part from base resin to finished part. We are ISO9001 & IATF16949 certified to be able assurance the part you qualify in the design remains consistent through production. Our Material including PTFE, Modified PTFE, PTFE compounds and high performance plastic. Contact our sales for your PTFE demand now.