Compression molding is an efficient manufacturing procedure used by many industries ranging from consumer products to automotive and even aerospace to manufacture products that are high-quality, and most importantly, functional.

This article will serve as a comprehensive guide on the compression-molding procedure as a leading manufacturing process. It will include how compression molding products are manufactured, how it serves as the right tool for engineers, designers, and mass producers, as well as unraveling the mystery of what the entire process entails.

What is Compression Molding?

Here, you will get to understand the meaning of compression molding, alongside intricate details about how compression molding takes place. Additionally, it includes various benefits and the corresponding disadvantages of this production process.

Definition of Compression Molding?

Compression molding is a production method that involves the use of heat, molds, and compression force in the form of high pressure. It involves melting molding materials, which are often rubber or plastic, that are preheated and then placed in a heated mold cavity before being compressed. The material produced often takes the design of the heated mold.

How Does Compression Molding Work?

In compression molding, there are various procedures involved, however, the constant step feature among all these procedures is that it begins with an empty mold cavity that requires a molding material.

A typical compression molding process begins when raw material (which can be rubber or thermoplastic) is fit into the mold cavity and a plug is then placed on top to seal the material to the cavity and also provide heat and pressure for optimal results.

The provided heat from the plug causes the thermoplastic to liquefy (by breaking down its sturdy molecular structure to a disorganized one) and expands in volume. The provided pressure ensures the thermoplastic expansion spreads evenly into the areas in the mold cavity.

The Pros & Cons of Compression Molding

Here are some of the advantages and disadvantages of compression molding;

Superior Surface Finish

Compared to many manufacturing procedures out there, compression molding guarantees a clean, superior surface finish each time. The heat and pressure ensure a fine dispersal of heated thermoplastics which reduces the time spent in refining finished products and hastens the process of production.

Great for Mass Production

Compression molding is great for producing a large number of products because the desired material is easily mounted in the mold cavity to be compressed and molded. Moreover, there is no limit to how much or how big the mold press can carry, allowing for several mold products to be produced.

Cost-Effective

Likewise, it is also cost-effective to run a compression mold as it possesses cheap setup tools that allow for medium and small scaled compression organizations to function easily. This is why it is cheaper to create sample prototypes before large-scale production commences.

Limitations

Alongside the highlighted benefits, there are some drawbacks facing this product process, one of such being the cost of after-molding. During heating and pressurizing, it is important to ensure the plug is placed carefully, else it may mold poorly, adding to the cost of post-molding design.

Two Types of Compression Molding Process

In this section, we will talk about the major kind of compression molding process. They are the hot and cold molding process; each kind offers different features and benefits and can be used with certain materials in certain situations.

Hot Compression Molding Process

The hot compression process, also known as the thermal compression process is the most used compression molding process in the manufacturing industry.

As its name suggests, it involves heating the material to a high temperature, thereby breaking down its strong molecular bonds, and softening the material before it is added to the mold cavity for extra heating and pressure.

There are some steps involved in the hot compression molding process and it begins with preheating, which means heating the material to a certain temperature to liquefy the material for easy mold filling.

Loading is another process that describes placing the preheated material in the cavity and compression is closing the mold plug to add more heat and pressure.

Cold Compression Molding

Cold compression molding, which is also known as room temperature compression molding describes a kind of manufacturing molding process that takes place at a temperature of 25°C.

Compared to hot compression which preheats the material first, the cold compression process molds the material at room temperature. The material is loaded into the mold cavity, compressed, and finally cured (additional post–compression steps such as adding additives.)

Cold compression molding is often employed for compression materials like thermoplastics and is used in the manufacture of several machine components such as seals, bellows, gaskets, and O-rings.

It consumes less energy and is suitable for materials that are heat sensitive or will degrade upon contact with high temperatures. Cold compression is preferred when dimensional accuracy is of high importance in product production.

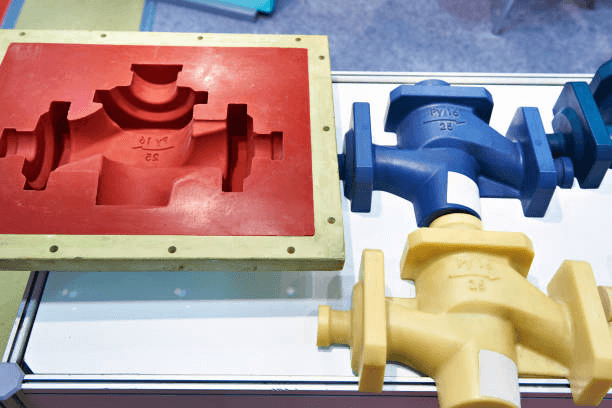

Three Types of Compression Molds

Compression molds are unique tools used in the compression molding process to design materials into special components in the presence of high heat and pressure. The three types of compression molds are flash type, positive type, and super positive type.

Flash Type

Flash-type compression molds are described as a kind of mold shape that is often preferred by many because of its ability to make simple compression molding products that still possess high density and thickness.

In compression molds, “flash” is often referred to as the excess mold material that comes out of the mold cavity during compression and pressurizing. Similarly, flash-type compression molds cause an over-spillage of mold material once the compression plug is mounted.

Positive Type

Positive-type compression molds feature a deep mold cavity that comes along with a plunger located beneath the cavity. Compared to flash-type compression molds that allow for material spillage and wastage, the positive type allows for little to no material escape. Hence, it is important to measure accurately when molding products that demand accurate size and density.

Positive-type compression molds are often in the production of high-impact materials such as Polystyrene (PS) and Acrylonitrile butadiene styrene (ABS) and components parts that demand a deep draw.

Semi-Positive Type

Semi-positive type compression molds combine the features of both flash-type molds and positive molds. It possesses similar parts and a flash ridge, alongside there it is built with the ground to limit the plunger’s travel. This distributes the compression pressure to the earth while distributing the necessary amount to the cavity mold.

In semi-positive compression molds, the level of clearance between the flash ridge helps in regulating the thickness between the flash and molded product.

Various Applications of Compression Molding Products

Compression molding is a versatile manufacturing process employed by both small and large companies to produce a wide range of objects ranging from usable household ware to creating unique parts for machines.

Here are common applications and benefits of compression molding products available for use in several industries;

Aerospace

The aerospace industry benefits heavily from compression molding products due to their strength, stability, and resistance to unfavorable environments. Since dimensional accuracy can be achieved via compression molding, the aerospace industry employs it to mold complex aerospace parts like aircraft panels and wing components.

Additionally, this process is also used to produce interior aerospace parts such as chairs, and tray tables since they are durable, lightweight, and sturdy enough to withstand constant use. It is also used to produce composite fan blades, aerospace gaskets, and seals that ensure airtightness which is important in aircraft fuel tanks and engines.

Automotive

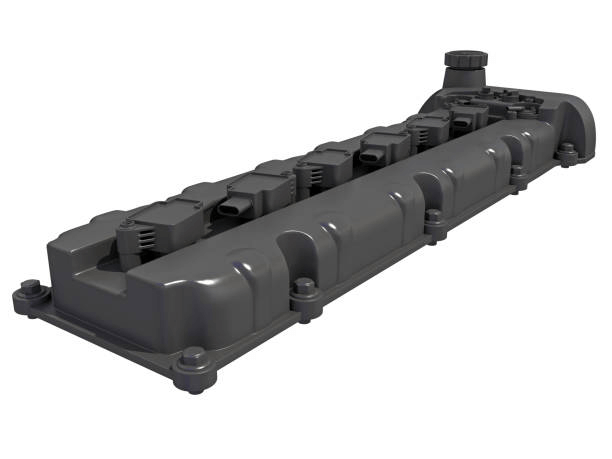

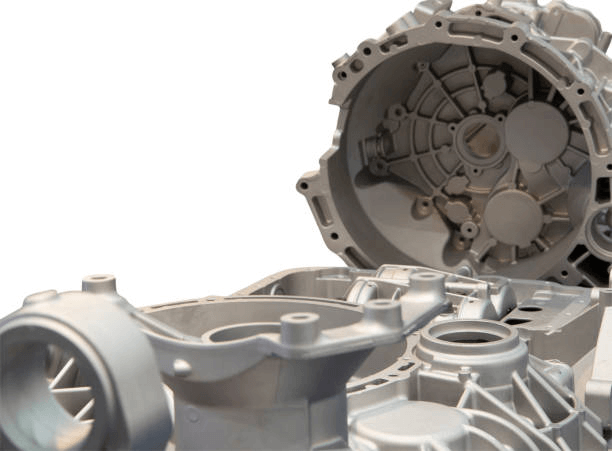

Likewise, the automotive industry uses compression molding products in numerous ways. One of the many uses is to manufacture automotive external body panels that allow for perfect surface finish, as well as preserving strength and stability.

It is also used to produce the interior components of automotive lis door panels and other aesthetic parts, promoting the quality of the components.

Compression molding products are also found in the engine of many automotive machines as it is used in the production of air ducts and valve covers. Overall, the automotive industry uses compression molding products in one way or the other in every car component.

Kitchenware

Compression molding products can also be found in our home, especially in our kitchen as many companies now produce kitchen utensils with them.

This is because compression molding products possess features such as heat resistance, resistance to wear and tear, and high durability; these are often the requirements in many kitchenware.

For instance, it is used in the production of pots and non-stick frying pans, and saucepans because of its inert property that prevents food components from sticking to its surface even under high temperatures. It is also used in producing food contact storage boxes that help in storing food for a long time.

Electronics and Semiconductors

Compression-molded products are used to create resistant and protective coatings or numerous electrical components such as sensors and connectors. This helps in dissipating heat, preventing electrocution, and insulation.

Likewise, it is used in manufacturing electrical terminals used in many devices as it can withstand high temperatures and also resist environmental degradation.

Compression molding products are used in producing LED lights that play an important role in the illumination of households, cars, aircraft, and virtually everything in the world. It is preferred because of its optical clarity and even light distribution that allows just one bulb to light up a whole pathway.

Medical

The medical world also uses compression molding products for a lot of things due to their sterility, and compatibility with biological components. It is used in making surgical components that require accurate dimensions and resistance to chemicals and blood.

Alongside this, it is used to produce dental parts that demand high accuracy and durability, allowing dentists to create custom-shaped parts for each patient.

Commonly Used Materials for Compression Molding

Various materials can be used during compression molding, however, thermoplastics and thermosets are often used because they offer better compatibility with the manufacturing process.

Thermoplastics

Thermoplastics is popularly used as a compression mold material due to certain features it exhibits. It allows for easy liquefying and processing, allowing for the use of the most minimal energy.

Polyethylene (PE), a common thermoplastic is favored for its highly resistive property to chemical and poor liquid absorption, and Polyamide (PA) is another durable thermoplastic known for its high thickness, serving numerous application purposes

Overall, thermoplastics offer combined properties of resistance, strength, ease of processing, and stability.

Thermosets

Likewise, thermoset materials are commonly used for compression molding because of their advantageous features and properties: high durability and low shrink rate. It also has a better surface quality and can be easily colored or changed without problems.

Thermosets are also ideal for creating small batch sizes without incurring wastage. They are highly resistant to heat and remain stable under unfavorable conditions.

Thermosets like phenolic resins are commonly used in compression molding in the electronics and semiconductor industry because of their insulating properties.

PTFE

Polytetrafluoroethylene (PTFE) is another common compression molding material.

The compression molding of PTFE begins when powdered resin PTFE is poured into a mold cavity and high temperature and pressure are added to transform it into a desired shape and size. Thereafter, it is removed from the cavity to solidify and modified into the finished product.

During molding, PTFE qualities can be enhanced by adding a blend of other materials such as carbon or graphite to create a better one. These enhancers or fillers can help improve its heat resistance and improve its durability and strength. Applications of PTFE molding include PTFE tubes, PTFE rods, PTFE films, and sheets.

PEEK

Polyether Ether Ketone (PEEK) is another thermoplastic used in many compression molds. Regular PEEK compression begins when fine powder grades or PTFE are preheated or directly poured into the mood cavity. The plug then mounts the required pressure and temperature and the product is cured after solidifying.

PEEK powder trains are preferred to PEEK pellets because the applied force in compression mold is unsuitable for pellets and would cause it to reduce certain features such as its mechanical performance. In addition, using PEEK pellets would also make it impossible to produce dense products that would not degrade upon heating or pressure.

Nylon

Nylon can be molded into different parts using compression molding. But before it is molded, it must first be in the form of powder or preheated solid.

Nylon has a high tensile strength, impact resistance, and wear resistance. These properties make the molded nylon part suitable for applications that requires strength and some level of resistance to impact and wears.

One of the reasons why nylon is commonly molded with compression molding is because of its thermoplastic nature. It can be melted and solidified over and over again and still remain firm.

Fibers (Glass & Carbon)

Glass fibers and carbon fibers are one of the most important materials used for compression molding. They are used to improve thermosetting resins to become composite materials with better physical and chemical properties.

Glass fibers are made in the form of mats or woven fabrics and placed in mold cavities during the compression molding of resins. The glass fiber will bond with the resin to provide the strength and stiffness that it lacks.

Carbon fiber has a similar property and mode of application. But it is preferred in applications that require high strength and lightweight.

Silicone Rubber

It is common to see silicone rubbers molded into different components using compression molding methods. This is because silicone rubber’s properties make them suitable for the processes involved in compression molding.

During the compression molding process, the silicone is mixed with a suitable curing agent. The mixture will then be placed in the mold cavity and heated and compressed to allow a crosslink between the curing agent and the silicone. This process can be used to produce gaskets, o-rings, and seals.

Polypropylene (PP)

Although compression molding is not the most suitable mold process for PP, it’s still in use by a lot of people. PP is a versatile thermoplastic that has a high resistance to impact, wear, and chemicals.

PP has a relatively low melting point compared to other materials. This makes it a suitable material for compression molding because the process requires heat.

In addition, PP has great dimensional stability which is why it can be easily subjected to compression molding process without diminishing in the process.

Sheet Molding Compound (SMC)

Sheet molding compounds are commonly molded using compression molding techniques. SMC are composite materials that are made up of resin and fibers (glass or carbon). They have a wide range of applications in different industries. Compression molding of SMC is used in the automotive industry for producing car body panels.

Bulk Molding Compound (BMC)

BMCs are also composite materials used in compression molding. They consist of thermosetting resins, reinforcements, fillers, and additives. BMC has a high strength and stability which makes them able to go through the process of compression molding and come out with a better product.

Like every other material used for compression molding, BMC is mixed and loaded into the heating cavity of the mold. The mold is designed to take the shape of the product that was designed. There is no compression molding without heat and pressure. The mold is then heated and pressure is applied to give a better result.

Ways to Create Compression Molds

Compression molds can be created in different ways. The three common ways of compression molding are 3D printing, die casting, and CNC machining.

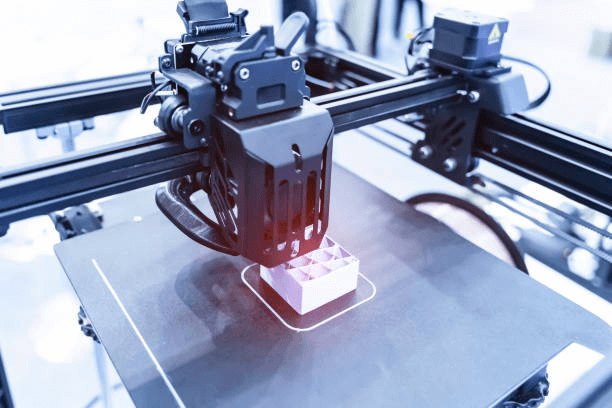

3D Printing

The tough part of 3D printing is the mold design, but that is not really tough if you have the technical know-how of CAD. 3D printing is an additive manufacturing technique that involves designing a mold and printing it layer by layer until the design is achieved.

One advantage of using 3D printing in compression mold making is that it will allow complex designs to be molded easily. In addition, it will also allow easy customization of molded parts. After printing these mold parts, the molds can now be used in compression molding for the product.

Die Casting

Die casting can be used to create molds for compression molding. Die casting is suitable for molding metals and other materials that can withstand the pressure of compression molding. The process of making a die-casted mold involves injecting molten metals under high pressure into die cavities that have been designed to fit the desired shape.

Once the die-casting process is complete, the mold is left to cool after which you are good to go on with designing your compressed products.

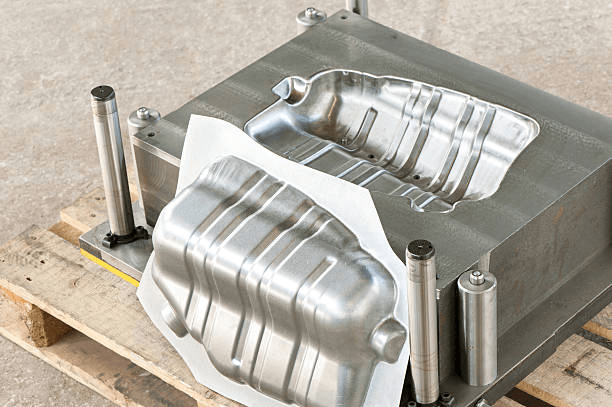

CNC Machining

CNC machining is the use of computers or robots for mold making, and it allows producers to make molds with tight tolerances and uniform dimensions that can closely adhere to design standards.

This ensures the dependability and quality of compression-molded components. The choice of material depends on factors like part complexity, required durability, temperature resistance, and cost considerations.

Get Premium Compression Molding Products From DCW

DCW is your one-stop sealing solution store thanks to our capability to produce, source, package, and transport items on time—even in an emergency.

We are China’s top compression molding experts and have helped thousands of clients actualize their dreams with our unique and customer PTFE molding services.

DCW: Top PTFE Compression Molding Experts in China

In addition to PEEK compression molding, we specialize in Oil & Gas Seals, Custom Seals, High-Temperature Seals, PEEK Molding, PTFE Molding, 3D-Printing, and many other high-performance products and services detailed on our website.

Our products and services have been a top choice for chemical processing, oil and gas, electronics and semiconductor, pulp and paper, medical, industrial, research & development, OEM, and other industries.

Near Net Shape & Purity PTFE Molding Available

At DCW, we can create basic shapes like blocks, tiny plates (rectangular or square), and PTFE rods and tubes in short sections.

We offer a variety of shapes, such as blank rough disks, “near net shapes”, and automatically molded components that are finished in all respects with no additional machining required. We also suggest designs and materials that will facilitate installation, cleaning, and maintenance for your business.

Some of our already-made neat shape products include bellows, ball valve seats, O-rings, insulators, guide rings, labware, seals, and bushings.

Conclusion

Compression molding is used in making functional goods; it is appropriate for both small and large-scale firms engaged in the manufacture of consumer goods or machine components.

DCW helps businesses make perfect goods made of compression-molded PTFE from DCW. These products include seals, bellows, and gaskets that have a smooth, less porous surface, improved permeation resistance, and longer flex life.

The workforce at DCW assists clients throughout the whole life cycle of the design process, including customer input and design, prototyping, tooling/mold production, and production.