PTFE is a versatile polymer with outstanding properties like chemical resistance, low friction coefficient (self-lubricating), non-stick nature, and excellent electrical insulation. However, it also has some limitations, and incorporating fillers can help overcome these limitations and further improve its certain properties to better suit specific applications. In a previous blog post, we explored the benefits of Glass-filled PTFE, and carbon filled PTFE. Today, we shift our attention to another remarkable filler: graphite.

Graphite filled PTFE combines the exceptional properties of PTFE with the unique attributes of graphite, unlocking a wide range of applications across various industries. In this post, we delve into the advantages and applications of graphite filled PTFE, highlighting its performance as a filler material.

What is graphite filled PTFE?

Graphite represents a crystalline form of exceptionally pure carbon, Its featuring a hexagonal arrangement of its atoms that form distinct layered structures. Graphite serves as a frequently employed filler in PTFE (polytetrafluoroethylene). The incorporation of graphite into PTFE results in a composite material with an impressively low coefficient of friction.

Moreover, Graphite exhibits outstanding wear resistance, especially when in contact with soft metals. In high-speed applications involving contact, graphite-filled PTFE demonstrates a remarkable ability to bear heavy loads. Additionally, due to its chemical inertness, it remains unaffected by various chemicals. As a consequence, graphite is commonly combined with other fillers to enhance and complement its properties.

Graphite, the Lubricant agent

Graphite, common know as dry lubricant agent. Lubricating agents are typically added to PTFE compounds to provide lubrication to the sealing material in applications where there’s a potential for it to be dry running. When graphite is added into PTFE compounds, they provide excellent wear performance due to lower coefficient of friction. Graphite fillers are excellent choices for dry running applications, even though this filler are typically used in combination with other fillers like glass fiber, carbon. Graphite by itself can be used up to 25% by weight in the PTFE. 10% and 15% graphite field PTFE compounds are commonly used in the industry.

Graphite filled PTFE also help, if there’s a situation where the hardware it is soft and lubrication could be a problem with sealing material being in contact with the hardware Surface.

Graphite filled PTFE is one of the most common materials support Rotary Shaft Seals product. graphite filled PTFE should not be used to soft water application. There’s a potential to with lubricating and agent that in graphite filled PTFE compounds, they may darken the media which they’re trying to seal.

Performance of graphite filled PTFE.

Graphite has self-lubricating properties which reduce friction. It is generally used in combination with glass or carbon or both. It has good wear resistance due to its flaky form.

- Extremely wear properties, Decrease wear, especially to soft metals

The presence of graphite in PTFE reduces friction and wear, which is especially beneficial when interacting with softer metal components, as it helps to minimize damage.

- Excellent lubricity due to flaky structure

Graphite’s flaky structure provides excellent lubricating properties, allowing the composite to reduce friction between mating surfaces effectively.

- Particularly good in wet environments for wear resistance

Graphite filled PTFE exhibits good wear resistance even in wet or moist environments, making it suitable for applications exposed to water or other liquids.

- Typically combined with carbon and glass in concentrations up to 5% to lower the coefficient of friction

- Cost-effective dry lubricant

Graphite filled PTFE is an inexpensive dry lubricant

- High concentration of 20% if good thermal conductivity is demanded, It is also a cost effective thermal control filler.

While graphite filled PTFE offers many advantages, it also has some limitations or weaknesses to consider:

- Not stable towards oxidising media, Not resistant against strong oxidizing agents.

- Graphite can cause blackening of medium, graphite may darken the media which they’re trying to seal. This might not be desirable in certain applications.

| Filler | Typical filler content by weight | Effects of the filler | Weakness of the filler |

| Graphite | 5% 10% 20% | Inexpensive dry lubricant Usually used as secondary filler in concentrations up to 5% Low coefficient of friction Used in concentrations of 20% for good thermal conductivity Good chemical resistance High thermal resistance | Not stable towards oxidising media High concentration if good thermal conductivity is demanded. |

Properties of graphite filled PTFE

Graphite-filled PTFE offers several benefits similar to standard carbon-filled PTFE, including a reduced coefficient of friction and excellent self-lubricating properties. However, it lacks the significantly improved wear resistance seen in carbon-filled PTFE. The advantage of graphite is that it can be combined with carbon, glass, or both to harness the combined benefits of all three fillers.

| Filler | Filler content | Specific gravity | Tensile strength (cross direction) | Elongation (Cross direction) | Hardness | Shrinkage rate | Other possible combinations |

| – | ASTM D4894 | ASTM D4894 | ASTM D4894 | Needle type | Internal Method | ||

| % | – | Mpa | % | Shore D | % | ||

| Non-filler | – | 2.17 | 31 | 310 | 57 | 3.0 | |

| Graphite | 15 | 2.16 | 20 | 200 | 61 | 2.4 | Carbon, glass fiber |

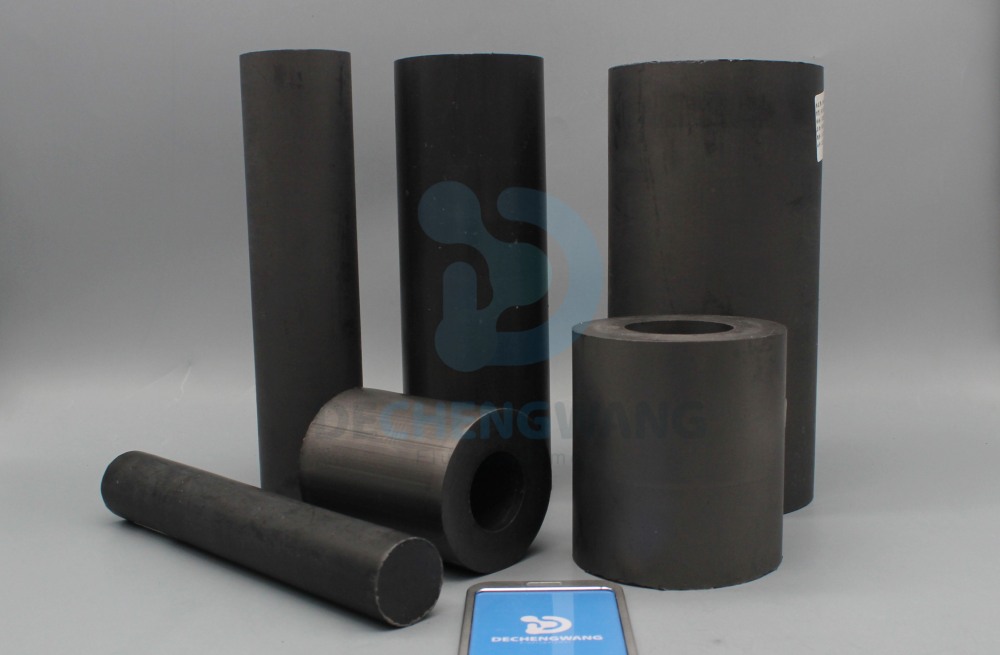

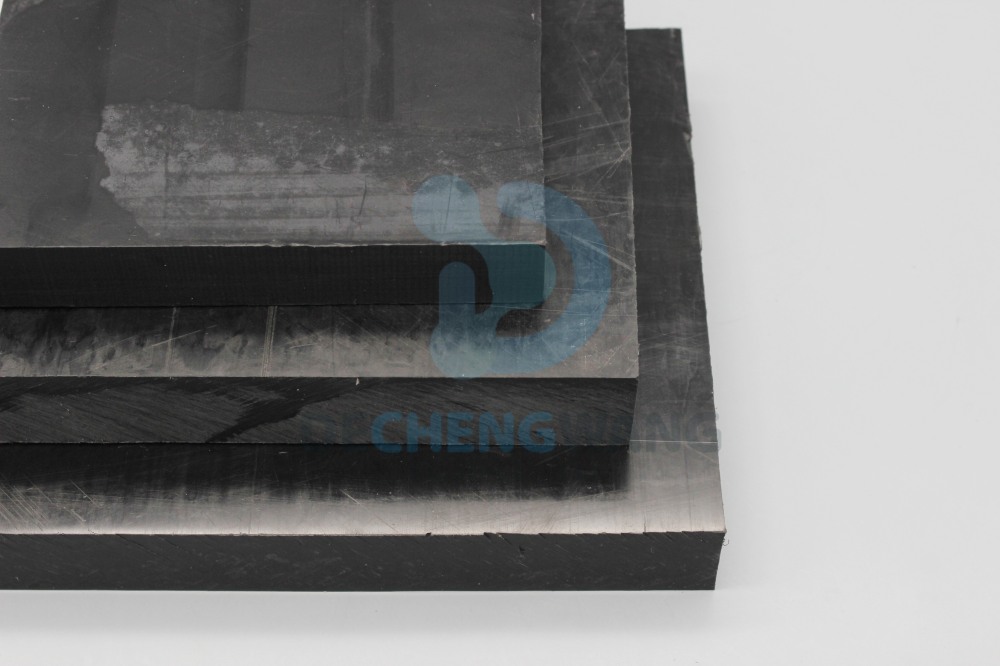

DCW available type of graphite filled PTFE products

- Custom make Parts

- Rod

- Sheet

- Tube

Application of graphite filled PTFE.

PTFE graphite offers excellent thermal conductivity, chemical inertness, and low friction, resulting in minimal wear to mating surfaces. The addition of graphite provides good chemical resistance in corrosive environments and enhances initial wear and sliding characteristics in both dry and water applications. It is commonly combined with carbon and PTFE for various applications.

Graphite-filled PTFE stands out for its remarkable chemical resistance and compatibility with most hydraulic fluids. It performs exceptionally well in hydraulic/pneumatic compression-type rod and piston seals, bearing bands, and rotary applications.

- Piston band for shock absorber

- Low friction applications

- camera pods, turrets

- Unlubricated service

- valve industry

- soft, dynamic countersurfaces

- water & steam application

DCW is one of the few PTFE manufactures to be fully integrated, having the capabilities to produce a part from base resin to finished part in China. We are ISO9001 & IATF16949 certified to be able assurance the part you qualify in the design remains consistent through production. Our Material including PTFE, Modified PTFE, PTFE compounds and high performance plastic. Contact our sales for your PTFE demand 1 now.