In order to make tubing for safe and temperature-sensitive applications, PFA tubing is used. Whether for making pumps and fittings, medical tubing, valve liners, and automotive tubing, PFA is utilized. For any applications where high temperature and high chemical resistance are needed, PFA is the ideal choice.

Due to the advantages of PFA, the PFA tubing is being utilized for numerous applications in several industries including but not limited to electronics, medical, laboratory, automotive, aerospace, etc.

Acquiring PFA tubing from a reputable PFA tube manufacturer is vital to ensure its quality and durability. Wondering what is PFA tubing, and what advantages and applications of Teflon PFA tubing? Check out this post.

What Is PFA Tubing

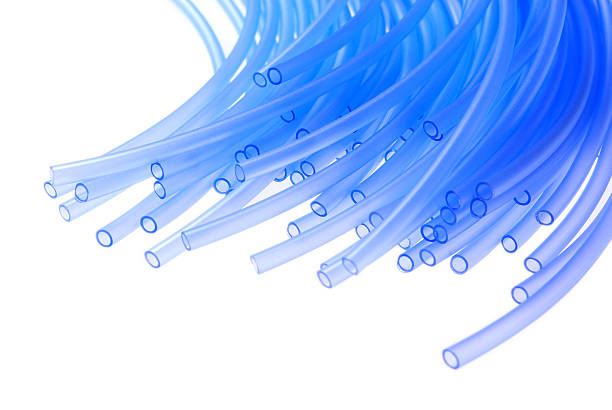

PFA tubing is also known as Perfluoroalkoxy tubing or fluoropolymer tubing. What is PFA tubing made of? It is a fluoropolymer that retains the incredible properties of Polytetrafluoroethylene (PTFE) and Fluorinated ethylene propylene (FEP) tubing. The Teflon PFA tubing features less melt viscosity compared to PTFE and high working temperatures of over +260 degrees Celsius than FEP.

Given the rigidity of the PFA tube, it is sometimes used in place of stainless steel tubes. PFA tubing is relatively versatile as it is used in a wide range of industries, even in chemically active methods, like lab techniques, heat exchanging applications, controlling the flow, electric insulation procedures, etc. Some primary properties of PFA tubes are

- Wide temperature range

- Chemically stable

- Dielectric strength

- Non-flammable

- Chemical resistance

- High purity

- Antistick properties

Advantages of PFA Tubing

The several advantages of PFA tubing, such as broad operating temperature range, less friction properties, resistance to UV, chemical resistance, and electrical insulation, make them ideal for a variety of applications.

High-Temperature Resistance

Temperature is an important aspect that needs to be considered for every application, regardless of the industry. For some applications, the temperature requirements can be -5 degrees Celsius, while other applications may have temperature requirements above 100 degrees Celsius.

Under such extreme operating temperatures, many materials are likely to get corroded, damaged, deformed, or crystallized, unlike PFA tubing. It is because the PFA tube has the potential to withstand PFA tubing operating temperatures ranging from -70 degrees Celsius to 260 degrees Celsius.

Chemical Resistance

The Teflon PFA tubing is also known for its incredible resistance to chemicals. Whether it is employed in applications where acids, corrosive chemicals, bases, or solvents are present, the PFA tubes will not react with the chemicals and remain safe.

Even powerful acids, organic and inorganic chemicals, or oxidizing agents can not affect the stability, reliability, and longevity of the PFA tubing. Because of the chemical-resistant property of PFA tubing, it is primarily the ideal choice in industries like chemical factories, laboratories, pharmaceutical factories, etc.

Low Friction Properties

It is not a new thing that even the tiniest amount of impurities in design have the potential to induce friction in the tube, which can result in mistakes and faulty outcomes at the time of tests. However, these kinds of circumstances can be easily avoided by using PFA tubing.

As a PFA tube consists of specialized formula, it features fewer friction properties, leading to an easy and smooth flow of the fluid. Because of the low friction, it decreases the pressures and flow resistance, so that gases or liquids can pass through the PFA tubes quickly and efficiently. The less friction makes it easy for maintenance and cleaning of the tubes.

Electrical Insulation

PFA tubing has low absorption properties and is also highly resistant to heat, which makes it the ideal choice for applications like valve linings, cable coating, insulating bushings, etc. By using Perfluoroalkoxy tubing, it will be easy to make sure the safety of electrical systems along with their performance, longevity and also deter electrical interference.

Because of being a good electrical insulator, PFA tubes can be used everywhere where it is vital to safeguard electrical parts from water or different impurities. In addition to that, PFA tubing does not subject to harm caused by tracking or arcing, so it is best to use it for applications that are associated with electrical fire dangers.

UV Resistance

For outdoor applications, especially those that are exposed to sunlight, using UV-resistant materials is often necessary. The majority of plastic materials will often be degraded or damaged due to UV radiation.

However, PFA tubing that is made by a reliable PFA manufacturer will not degrade when exposed to UV because it shows immense resistance to UV radiation.

Applications Of PFA Tubing In Various Industries

From aerospace to electronics, medical to laboratory, food and beverage processing to semiconductor applications, one can easily find PFA tubing in a wide variety of industries, given their incredible properties and advantages.

Semiconductor And Electronics

The semiconductor and electronics industries mainly use PFA tubing for a variety of applications. Some of them include making PCBs, encapsulating semiconductor appliances, moving gases and chemicals, and many more.

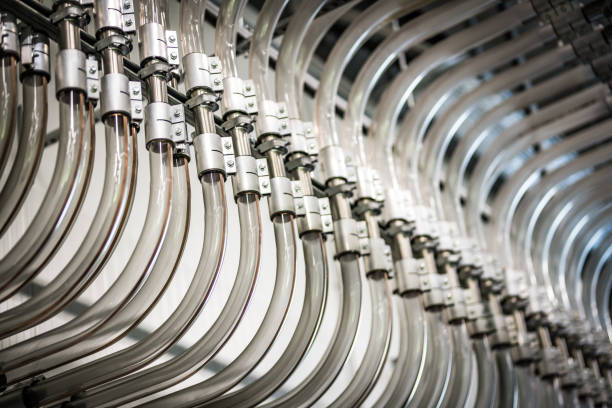

For electrical insulation, pumps, valves, heat exchangers, and many other applications associated with the microelectronic device industry, PFA tubes are primarily utilized. The main reason PFA tubing is given importance in the electronic and semiconductor industry is because of its capacity to safely handle fluids.

Medical And Laboratory

When it comes to medical, pharmaceutical, and laboratory industries, it is heavily important to use safe, non-corrosive tubes that do not reach chemically or degrade the stored content inside. Because of that reason, PFA tubing is preferred for such applications to ensure the pureness of the content intact.

The PFA tubes are used for passing liquids and gases, attaching medical appliances, keeping aside dangerous substances, and many more. In addition to that, PFA tubing is also employed in various laboratory applications, including but not limited to cell culture, chemical analysis, sequencing of DNA, etc.

Automotive And Aerospace

In the aerospace and automotive industries, there are many applications that are associated with high-pressure, extreme operating temperatures, and hazardous substances. In such circumstances, the safest choice is to use PFA tubes. In the AC lines, fuel and coolant lines, hydraulic lines, oxygen lines, braking systems, and many more, the PFA tubing is utilized.

DCW: Your Trusted Provider of High-Quality PFA Tubing

With a combined 13 years of experience in manufacturing best quality PFA tubes and material selection, DCW is one of the leading manufacturers and suppliers of PFA tubing. We offer customized PFA tubes that align with the client’s specific needs and ensure the quality and durability of our products.

Quality Assurance

We have an in-house manufacturing facility where state-of-the-art machines and the latest technology are used to produce high-quality PFA tubes. We follow IATF/ISO global manufacturing standards and conduct quality inspections like appearance checks, tensile strength tests, density tests, and dimension measurements to ensure 100% quality of our products.

Our manufacturing factory has several certifications, including ISO 9001 2015 Quality Management System Certification 2018, ISO 14001 2015 Environment Management System Certificate 2018, Intellectual Property Managements Certificate 2019, National High-tech Enterprise Certificate, IATF-16949-2016, and Shenzhen High-tech Enterprise Certificate.

Customization Options

Our experts can customize the manufacturing of high-quality PFA tubing from custom material selection, custom shape, and custom processing techniques. In addition, we do not have any minimum order quantity for custom PFA tubing orders.

Conclusion

PFA tubing is the ultimate choice for high-temperature and high-pressure applications that deal with highly dangerous substances. So, it is important to acquire and use only the highest quality PFA tubes.

DCW offers the best quality, durable, and safe PFA tubing made from high-quality materials and underwent numerous quality inspections. We ensure 100% quality assurance, offer custom PFA tube products, and have no MOQ. Contact DCW right away to get instant quotes on PFA tubing and receive your orders quickly.